Anatomy of a Copper Base Circuit Board

A copper substrate PCB consists of three fundamental layers, each playing a critical role in performance and reliability:

- Circuit Layer: This topmost layer contains the copper traces that form the electrical pathways. Typically made from high-purity copper such as C1100, it offers excellent electrical conductivity and supports current flow with minimal loss.

- Dielectric Layer: Positioned between the circuit and the base layer, this insulating material provides electrical isolation while maintaining strong thermal conductivity. The dielectric constant and thermal expansion coefficient are carefully controlled to optimize signal integrity and heat dissipation efficiency.

- Base Layer: The foundation is a solid copper metal core that serves as a heat sink. Copper’s superior thermal conductivity (approximately 390 W/m·K) enables effective thermal management, critical in high-power applications.

When comparing copper substrates to aluminum alternatives, several factors emerge:

- Thermal Conductivity: Copper outperforms aluminum (about 205 W/m·K) in heat transfer, reducing thermal resistance (Rth) and improving device longevity.

- Machinability: While aluminum is lighter and easier to machine, copper offers greater mechanical stability under thermal cycling, which is essential for advanced multilayer PCBs.

- Cost-to-Performance Ratio: Copper substrates have a higher upfront cost but provide better thermal management and reliability, particularly in high-current or high-temperature environments, justifying the investment in sectors like automotive inverters and LED lighting.

Understanding these material distinctions is fundamental to selecting the right substrate for demanding electronic assemblies requiring efficient heat dissipation and consistent electrical performance.

Advanced Technology: Thermoelectric Separation and Direct Thermal Path

Thermoelectric separation technology is a game changer in copper substrate PCB design. By creating a direct thermal path, it drastically reduces thermal resistance, allowing heat to flow straight from heat sources to the copper base with almost no barriers. This results in much better heat dissipation efficiency critical for high-power applications like LED lighting and automotive electronics.

How the Architecture Works

- Direct Thermal Path: Unlike traditional structures with insulating barriers, this method uses a copper core connected through blind vias to the heat source.

- Blind Via Plating: These plated vias connect the top circuit layer directly to the copper base without passing entirely through the board, minimizing heat buildup.

- Protrusion Processing: Copper protrusions on the base layer increase contact area, improving heat transfer and mechanical strength.

| Feature | Benefit |

|---|---|

| Thermoelectric separation | Nearly zero thermal resistance (Rth) |

| Blind via plating | Strong, reliable thermal conduction |

| Protrusion processing | Enhanced heat spreading and durability |

Manufacturing Benefits

This process elevates the thermal conductivity (W/m·K) of the PCB naturally while maintaining electrical insulation. Using blind via plating and protrusion processing reduces the number of thermal barriers, ensuring consistent and effective cooling. This makes the copper substrate ideally suited for Metal Core PCB (MCPCB) fabrication where managing heat is crucial.

For efficient production and optimal thermal results in LED assemblies or power electronics, this advanced layering approach is essential.

Explore how our custom copper substrate LED PCB assembly services utilize these cutting-edge processes to meet demanding thermal management needs.

Heavy Copper and Multilayer Capabilities

Copper substrate PCBs with heavy copper layers are built to handle high current loads, making them ideal for power supply units (PSU) and automotive inverters. The increased copper thickness boosts current-carrying capacity and improves heat dissipation, which is crucial in high-power environments. These PCBs often feature multilayer construction to optimize electrical performance and thermal management.

Multilayer copper substrate PCB stacking is more complex due to the need for plated through-holes that connect layers electrically while maintaining insulation. Managing insulation between layers is critical to prevent electrical shorts and maintain dielectric breakdown voltage. Advanced resin plugging and via filling techniques are commonly used to fill blind and buried vias, preventing material leakage and ensuring strong mechanical stability.

These multilayer configurations also support heavy copper circuitry, which is essential for industrial applications requiring reliable power conduction and thermal resistance management. If you\’re exploring multilayer designs for automotive power electronics or high-current LED assemblies, reliable manufacturing processes are key to balancing complexity and performance.

To understand how to optimize your PCB design for heavy copper layers and multilayer stacking, check out our detailed LED PCB design resources for insights relevant to high-power assemblies in automotive and industrial sectors.

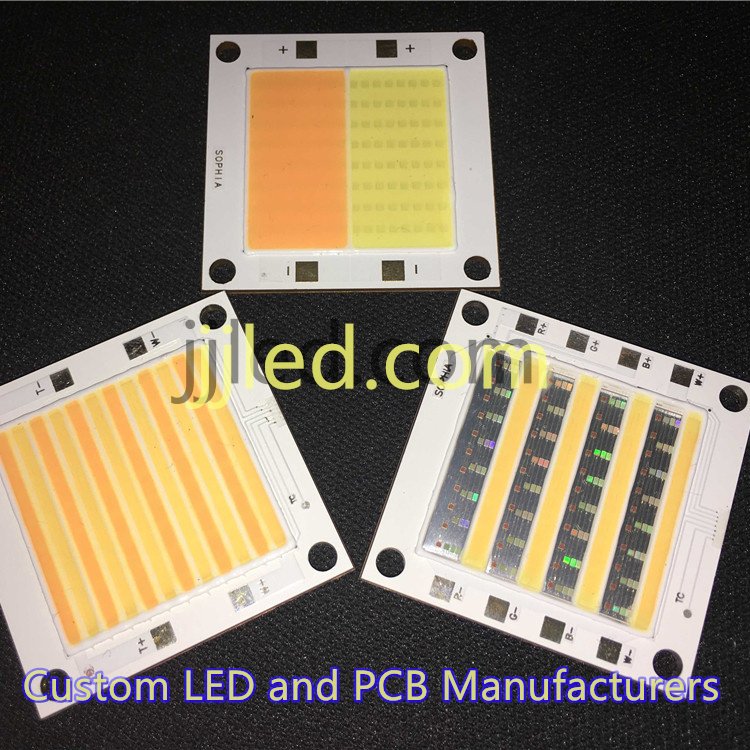

Critical Application Areas for Copper Substrate PCBs

Copper substrate PCBs are essential in sectors demanding superior heat dissipation and reliable electrical performance. High-power LED lighting is one of the top applications where these boards excel. Their excellent thermal conductivity ensures LEDs run cooler, extending both lifespan and efficiency. Whether it\’s streetlights, commercial fixtures, or specialty lighting, copper base PCBs handle high currents and heat with ease.

In automotive electronics, copper substrates are critical for EV battery management systems and headlight modules. These components require stable thermal and electrical properties to maintain safety and functionality under heavy loads and fluctuating temperatures. Copper substrate PCBs provide the heat dissipation and durability needed for rugged automotive conditions.

Industrial power conversion systems also benefit greatly from copper substrate technology. The high thermal conductivity and low thermal resistance (Rth) enable efficient handling of high currents and voltages in inverters and power supplies. This is vital for ensuring long-term reliability and consistent performance in demanding industrial environments.

For related high-power LED lighting solutions, you might find our custom high-power aluminum LED PCB options useful as complementary technologies in thermal management.

DFM for Copper Substrates: Tolerances, Finishes, and Solder Mask Considerations

Design for Manufacturing (DFM) plays a crucial role when working with copper substrate PCBs, especially given their thermal demands and precision needs. One common challenge is managing tight tolerances during drilling. Heavy copper layers require more robust drill bits and careful control to avoid delamination or excessive wear, so specifying accurate hole sizes and drill paths upfront saves time and reduces defects.

Surface finish selection is another critical factor. For copper-based PCBs, ENIG (Electroless Nickel Immersion Gold) is often preferred for its excellent solderability and corrosion resistance. Alternatively, OSP (Organic Solderability Preservative) can be a cost-effective option but may not withstand multiple heat cycles as well as ENIG. Both finishes impact long-term reliability and affect thermal conductivity to some extent, influencing overall heat dissipation efficiency.

Solder mask choice must also match the intense thermal environment frequently seen in high-power assemblies. Using solder masks rated for high-heat reflow processes ensures coatings won\’t crack or peel during manufacturing, preserving the assembly\’s integrity. Proper mask application helps avoid solder bridging while supporting consistent electrical insulation on copper substrates.

By aligning drilling specifications, surface finishes like ENIG or OSP, and heat-resistant solder masks in your copper substrate PCB design, you’ll set a stable foundation for robust, manufacturable boards optimized for thermal and electrical performance.

For more detailed insights on surface finish options and their roles in LED PCB assemblies, check out our guide on custom high CRI 2835 LED round PCB board.

Choosing a Copper Substrate PCB Manufacturer in China

When selecting a manufacturing partner for your copper substrate PCB needs, especially for high-demand applications like LED lighting or automotive power electronics, quality metrics are crucial. Look for suppliers who provide thorough dielectric breakdown testing to ensure excellent insulation resistance and verify thermal conductivity certification to guarantee efficient heat dissipation. These tests confirm the substrate’s ability to handle high thermal loads without failure.

Customization and prototyping are equally important. Working with a manufacturer experienced in tailored copper substrate LED PCB board assembly services lets you optimize your design with precise copper thickness, specific layer stacks, and surface finishes like ENIG—vital for your product’s performance and reliability. A trusted partner will support quick turnaround prototypes, allowing you to validate thermal and electrical characteristics before full production.

Ready to move forward? Submit your Gerber files early and request a comprehensive thermal analysis. This ensures your design leverages advanced features such as direct thermal paths and blind via plating, which significantly improve performance. For reliable China-based copper substrate manufacturing, consider suppliers with proven expertise in these areas, like the custom copper substrate PCB assembly services at JJLED, to streamline your product development.

By partnering with a capable manufacturer, you can unlock better heat dissipation efficiency, improved dielectric breakdown voltages, and ultimately, a more robust PCB tailored for your application.