Understanding the 3535 LED Package: Size, Structure, and Power

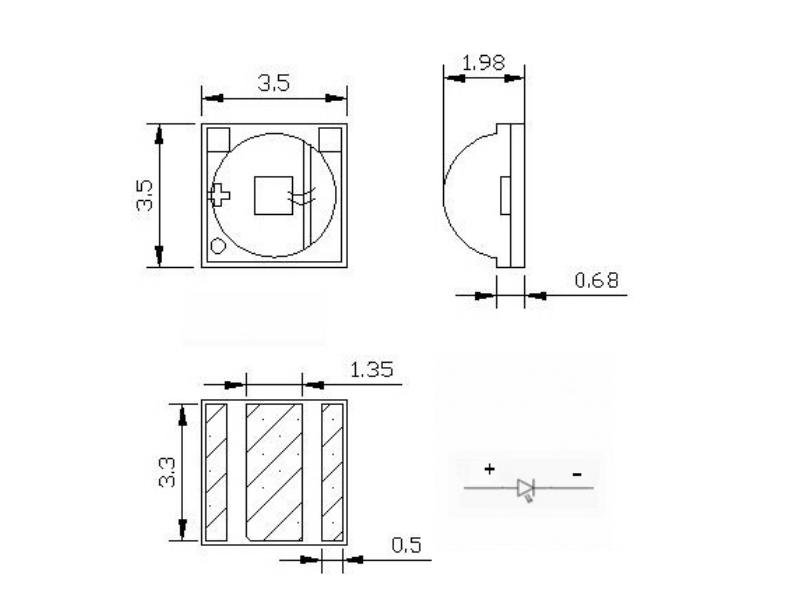

When looking at 3535 LED chips, the first thing to know is their physical size and build. The “3535” name comes from the package dimensions — 3.5mm x 3.5mm — making it a compact yet robust LED solution.

Physical Dimensions and Structure

- Size: 3.5mm by 3.5mm square surface

- Base Material: Usually ceramic or EMC (Epoxy Molding Compound)

- Benefits: Ceramic bases offer better thermal conductivity and durability, ideal for high-power applications, while EMC is cost-effective for standard uses.

Common 3535 LED Chip Technologies

- Flip Chip: Chip is mounted upside down, reducing thermal resistance, improving heat dissipation, and enhancing brightness — great for high-power and demanding applications.

- Vertical Chip: Traditional mounting with a vertical structure, easier to manufacture, suitable for mid-power LED lighting.

| Feature | Flip Chip 3535 LED | Vertical Chip 3535 LED |

|---|---|---|

| Thermal Conductivity | Superior | Standard |

| Brightness | Higher | Moderate |

| Cost | Slightly higher | More affordable |

| Application | High-power and industrial | General lighting |

Power Ratings: From 1W to 5W

3535 LED chips span a wide power range, typically from 1 watt to 5 watts, making them versatile for various lighting needs:

- 1W–3W: Mid-power general lighting, indicator lamps

- 3W–5W: High-power LED applications requiring strong luminous output and excellent heat management

In , the 3535 LED package is a flexible platform offering various chip technologies and power options, suited for applications demanding reliability, efficient thermal management, and strong performance within a compact size.

Technical Specifications of 3535 LED Chips

Understanding the technical specs of a 3535 LED chip helps you choose the right one for your project. These chips offer a balance between power, efficiency, and versatility.

Electrical Characteristics

| Parameter | Typical Range |

|---|---|

| Forward Voltage | 2.8V – 3.4V |

| Forward Current | 350mA – 1500mA |

| Power Rating | 1W to 5W (high power options) |

Most 3535 LEDs operate efficiently within this voltage and current range. The forward voltage varies slightly depending on the type (white, RGB, UV, IR).

Optical Performance

| Parameter | Values |

|---|---|

| Luminous Flux | 80lm – 500lm+ |

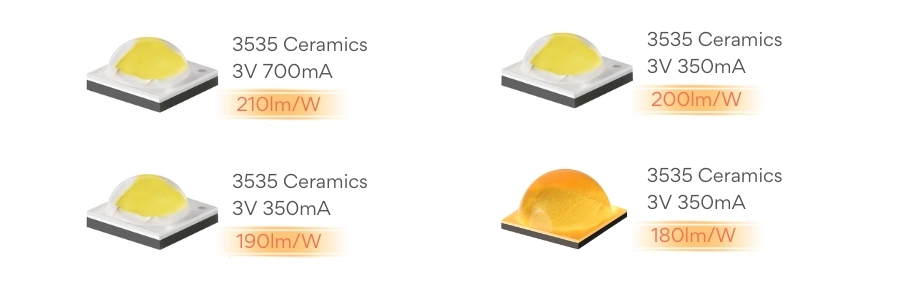

| Efficacy | 90 – 160 lm/W |

| Color Rendering Index (CRI) | 70 to 95+ |

| Correlated Color Temperature (CCT) | 2700K – 6500K (White LEDs) |

The CRI is important for applications needing natural color tones, such as horticulture or architectural lighting. Luminous efficacy values ensure energy efficiency while maintaining brightness.

Color and Wavelength Options

- White LEDs: Various CCTs from warm (2700K) to cool (6500K)

- RGB: Allow full-color mixing, great for dynamic lighting effects

- UV and IR: Used in curing, sensing, and therapy devices

- Horticulture-Specific LEDs: Optimized wavelengths for plant growth (typically red and blue spectrum peaks)

Viewing Angle and Beam Distribution

3535 LED chips typically feature viewing angles between 120° to 150°, delivering a wide, even beam distribution. This makes them ideal for floodlights and area lighting where broad coverage is needed.

For detailed LED design considerations, exploring our LED light circuit board design page can give you more insights on pairing these chips with the right PCB for optimal performance.

Knowing these key specifications lets you select the right 3535 LED chip type for your specific lighting needs.

3535 LED Chips vs. Other Popular Packages

When comparing 3535 LED chips to other common packages like 2835 and 5050, there are clear differences in performance, power, and applications.

| Feature | 3535 LED Chip | 2835 SMD LED | 5050 SMD LED |

|---|---|---|---|

| Size | 3.5mm x 3.5mm | 2.8mm x 3.5mm | 5.0mm x 5.0mm |

| Typical Power Range | 1W to 5W (high power) | 0.2W to 0.5W (mid power) | 0.2W to 0.5W (mid-high power) |

| Efficiency | High thermal efficiency | Good efficiency, cost-effective | Moderate efficiency |

| Brightness | High brightness for size | Moderate brightness | High brightness, especially in RGB |

| RGB Capability | Available but more limited | Less common | Native RGB with multi-chip design |

| Thermal Performance | Superior, ceramic or EMC base | Standard PCB-based | Standard PCB-based |

| Common Uses | Industrial, horticulture, high-power lighting | General indoor, residential lighting | RGB lighting, decorative use |

When to Choose 3535 LED Chips

- You need reliable high power (1W to 5W) output

- Your design requires better heat dissipation for longer life and stable performance

- You want versatile color options beyond white, including UV, IR, or high-CRI white

- Your application demands higher brightness than typical mid-power LEDs

- You aim for industrial or outdoor lighting, where thermal management is crucial

For mid-power, cost-sensitive projects, 2835 LEDs are often a better fit. For vibrant RGB or multi-color setups, 5050 LEDs remain popular due to their integrated multi-chip design.

Learn more about differences in LED packages and when to use each in our detailed 2835 LED guide and overview of popular LED lighting products.

Choosing 3535 LED chips balances power, thermal management, and versatility—perfect for demanding lighting needs.

Key Applications of 3535 LED Chips

3535 LED chips are incredibly versatile, making them a popular choice across a wide range of lighting needs worldwide. Their high power and excellent thermal performance open doors for many demanding applications.

Outdoor and Industrial Lighting

Thanks to their robust design and strong output, 3535 LEDs are perfect for street lights, floodlights, and high bay fixtures at warehouses and factories. Their ability to deliver bright, consistent light with efficient heat dissipation ensures long lifespan in harsh outdoor environments.

Horticulture and Plant Growth Lighting

Specialized 3535 LED chips tailored for horticulture provide the precise light spectrum plants need for growth, boosting photosynthesis and yield. This makes them great for indoor farming setups and greenhouses. Their customizable wavelength options enable fine-tuning for different plant stages.

Stage, Architectural, and Landscape Illumination

For creative lighting in architecture and landscape design, 3535 LEDs offer flexibility with color options like RGB and high CRI white LEDs. Their compact size lets designers create dynamic lighting effects without bulky fixtures, enhancing visual impact both indoors and outdoors.

Specialized Uses: UV Curing, IR Sensing, and Therapy Lighting

Beyond visible light, 3535 LED chips come in UV and IR variants ideal for industrial UV curing, IR sensing devices, and medical therapy lights. These niche applications benefit from the chip’s stable output and efficient heat management.

For more on lighting quality, consider exploring high CRI options that improve color rendering in your applications, which you can find detailed in our guide on the benefits of high CRI lighting.

Overall, 3535 LED chips provide a versatile, reliable solution across many sectors, backed by strong performance and thermal management advantages.

Thermal Management and PCB Design Considerations

Heat dissipation is vital when working with high-power 3535 LED chips. These LEDs can generate significant heat during operation, which can reduce efficiency, shorten lifespan, and cause reliability issues if not managed properly. Ensuring good thermal management helps maintain consistent performance and long-term durability.

Best Practices for 3535 LED PCB Boards:

- Use materials with high thermal conductivity like ceramic or aluminum MCPCB to draw heat away quickly.

- Design large copper pads under the 3535 LED chip to assist heat transfer.

- Incorporate thermal vias to lead heat from the LED side to the opposite PCB layers efficiently.

- Maintain proper spacing between LEDs to minimize heat build-up.

- Avoid excessive current which can create unnecessary heat and stress the chips.

Understanding thermal resistance ratings for your LED and PCB stack-up is key. Lower thermal resistance means better heat dissipation, which translates to stable light output and longer lifespan.

For detailed insights into designing effective 3535 LED PCBs, explore our guide on design considerations for LED circuit boards and how to optimize LED PCB thermal management to enhance the performance of your lighting solutions.

Proper thermal management paired with well-planned PCB design ensures your 3535 LED chips perform reliably at their full power potential.

Custom 3535 LED Chips and PCB Solutions

Customizing 3535 LED chips and PCB boards lets you fine-tune performance precisely for your needs. Whether you require specific wavelengths, power ratings, or a high CRI (Color Rendering Index), customization improves efficiency and application fit.

Benefits of Custom 3535 LED Chips

- Tailored Wavelengths: Choose exact colors for horticulture, UV curing, or IR sensing.

- Power Options: From 1W to 5W chips matched to your thermal design.

- High CRI: Ideal for stage lighting and architectural projects requiring natural colors.

Manufacturing Process Overview

Custom 3535 LED chips start with selecting the base package (Ceramic or EMC). Then, chip technology like flip-chip or vertical chips is applied based on desired brightness and thermal needs. Finally, specialized phosphors or coatings are added for color control.

Sourcing Reliable Custom 3535 LED Chips and PCB Boards

To get dependable custom LED solutions:

- Verify supplier certifications and datasheets.

- Choose manufacturers who offer transparent specs and quality control.

- Opt for producers experienced with thermal management and custom PCB layouts.

We recommend using professional manufacturers who provide end-to-end support for custom 3535 LED chip and PCB board designs, like those featured in our detailed custom LED board solutions and LED PCB manufacturing processes.

| Key Customization Factor | Benefit | Application Example |

|---|---|---|

| Wavelength Control | Targeted light output | Horticulture, UV curing |

| Power Range | Optimized energy use | Industrial lighting |

| CRI Adjustment | Better color rendering | Architectural lighting |

| PCB Design | Enhanced heat dissipation | High-power LEDs |

Custom 3535 LED chips and LED PCB boards give you the flexibility and performance boost needed for specialized lighting projects worldwide.

Buying Guide: Selecting the Right 3535 LED Chip

Choosing the right 3535 LED chip can make all the difference in your lighting project. Here are some key factors to keep in mind:

Factors to Consider

- Brand Reputation: Go for established manufacturers known for quality and consistency. They usually provide better datasheet accuracy and after-sales support.

- Datasheet Verification: Always review the 3535 LED datasheet carefully. Check electrical specs like forward voltage, current rating, and luminous flux to ensure they meet your needs.

- Certifications: Look for certifications like RoHS, CE, or UL, which guarantee product safety and compliance with international standards.

Common Pitfalls to Avoid

- Ignoring thermal management needs, which can drastically reduce LED lifespan.

- Relying solely on price — cheaper chips often compromise on brightness or lifespan.

- Overlooking the compatibility of the LED chip with your PCB board design.

Supplier Recommendations for Quality and Support

- Pick suppliers that offer reliable technical support and customization options for tailored solutions like power rating and color tuning.

- Consider manufacturers who specialize in 3535 LED PCB boards and chips for better integration and optimized thermal design.

For detailed insights into successful LED PCB manufacturing and material choices, explore our guide on how 3535 LED PCBs are manufactured. This will help you avoid common mistakes and ensure a durable final product.