If you’re working with 3535 SMD LEDs and need a PCB that delivers top-tier performance, then understanding the value of a custom 3535 LED PCB is crucial. These high-power LEDs demand more than just any circuit board—they require precision design and exceptional thermal management to unlock their full potential. That’s where copper substrate PCBs come in, offering superior heat dissipation and durability, especially for demanding lighting applications like automotive, street lights, and grow lights. In this guide, you’ll discover why choosing a custom copper substrate 3535 LED PCB can transform your project’s efficiency, reliability, and brightness. Let’s get straight to why this choice matters for your next lighting solution.

What is a 3535 LED PCB?

A 3535 LED PCB refers to a printed circuit board designed specifically for mounting 3535-sized surface-mount device (SMD) LEDs. The \”3535\” denotes the LED package dimensions: 3.5mm by 3.5mm. This size is popular among leading LED manufacturers like Cree, Nichia, and Samsung for its balance between compact form and high brightness output. These LEDs are widely used in applications requiring robust illumination with efficient heat management.

Custom 3535 LED PCBs come in various configurations to suit different needs. You can find single-star boards designed to hold one LED, multi-LED arrays that increase light intensity, or linear modules tailored for specific shapes and lighting patterns. Whether standard or custom, these PCBs are engineered to optimize the performance of 3535 SMD LED boards.

The role of the PCB goes beyond simply holding the LED. It supports consistent power delivery while managing heat dissipation efficiently, which is critical because 3535 LEDs, especially in high-power applications, generate significant heat. A well-designed copper substrate LED PCB ensures thermal management, helping to reduce junction temperatures and maintain long-term reliability and brightness stability. This combination makes custom 3535 LED PCBs with copper substrates an ideal choice for demanding lighting solutions.

Why Choose Copper Substrate for 3535 LED PCBs?

When it comes to 3535 LED PCBs, the choice of substrate greatly impacts performance. The main options are copper, aluminum, and FR-4, but copper substrate stands out for several reasons.

| Substrate Type | Thermal Conductivity | Heat Spreading | Durability | Cost | Typical Use |

|---|---|---|---|---|---|

| Copper | Excellent | Superior | High | Medium-High | High-power LED MCPCB, automotive, outdoor lighting |

| Aluminum | Good | Good | Medium | Medium | Standard LED boards, some high-power applications (Aluminum LED PCBs) |

| FR-4 | Poor | Limited | Low | Low | Low-power electronics, general PCBs |

Key advantages of copper substrate for 3535 SMD LED boards:

- Superior thermal conductivity: Copper dissipates heat far better than aluminum or FR-4. This keeps junction temperatures low, critical for high brightness LEDs like those in 3535 packages.

- Better heat spreading: Copper evenly distributes heat, avoiding hotspots that can degrade LEDs or cause uneven light output.

- Enhanced reliability: Lower operating temperatures extend LED lifespan and improve performance stability over time.

Real-world benefits include:

- Reduced LED junction temperatures, preventing early failures.

- Longer overall lifespan for the LED module.

- Stable brightness with less risk of dimming or color shift under continuous operation.

Choosing a copper substrate LED PCB for your 3535 LEDs is a smart move for applications needing reliable thermal management and consistent high performance. For more on substrate differences, check out our guide on custom high power aluminum LED PCBs.

Benefits of Copper Substrate PCBs for High-Power 3535 LEDs

Using copper substrate PCBs for high-power 3535 LEDs brings several clear advantages, especially for demanding applications:

| Benefit | Description |

|---|---|

| Exceptional Thermal Management | Copper’s superior heat dissipation keeps junction temperatures low, vital for high-wattage LEDs to avoid overheating and maintain performance. |

| Improved Electrical Performance | Copper offers better current carrying capacity and lower resistance compared to aluminum or FR-4, ensuring stable power delivery to 3535 LED arrays. |

| Greater Durability | Copper substrate PCBs withstand harsh conditions, making them ideal for outdoor lighting, automotive headlights, and industrial environments. |

| Cost-Effectiveness | Better thermal and electrical efficiency reduce cooling needs and failure rates, saving money on maintenance and replacements over time. |

These benefits make copper substrate LED PCBs the preferred choice for high brightness LED circuit boards and custom LED module designs where reliability and longevity are key. For demanding projects like automotive 3535 LED boards or street light LED modules, copper PCBs provide the thermal management and durability needed to excel.

Key Design Considerations for Custom 3535 LED Copper PCBs

Designing a custom 3535 LED PCB with a copper substrate requires careful attention to several factors to ensure top performance and reliability. Here’s what to focus on:

Layout and Pad Design

Precise pad layout is essential for smooth soldering and proper alignment of the 3535 SMD LED packages. It helps avoid cold joints and improves mechanical stability, especially in single stars or multi-LED arrays.

Thermal Vias, Trace Width, and Copper Thickness

Efficient heat dissipation depends on optimizing thermal vias that connect layers to spread heat away from the LEDs. Wider copper traces and thicker copper plating also enhance current carrying capacity and reduce resistance, which is crucial for high power LED MCPCBs.

Dielectric Layer Selection

The dielectric layer acts as an insulator between copper layers while facilitating heat transfer. Choosing the right dielectric material balances electrical isolation with excellent thermal conductivity.

Compatibility with Optics, Drivers, and Enclosures

The PCB design must fit seamlessly with optical components and LED drivers for stable operation. The size, shape, and mounting points should also align with enclosure requirements to avoid mechanical stress or misalignment.

Common Pitfalls to Avoid

Watch out for design flaws like overheating hotspots or uneven light distribution caused by poor layout or insufficient thermal management. These can shorten LED lifespan and reduce overall module efficiency.

For a deeper understanding of these factors, checking detailed resources on design considerations for LED circuit boards can help guide your custom PCB projects.

By addressing these key design points, your custom 3535 LED copper substrate PCB will deliver improved thermal management, electrical performance, and long-term reliability tailored to your specific application.

Applications of Custom 3535 LED PCBs with Copper Substrates

Custom 3535 LED PCBs with copper substrates are highly versatile and used across various demanding lighting applications due to their excellent thermal management and reliability. Here are some common uses:

- Street and outdoor lighting: These PCBs handle high power and heat, making them ideal for durable street light LED modules that need to perform consistently in changing weather.

- Automotive headlights and signaling: The automotive 3535 LED boards deliver bright, stable light required for headlights and indicators while enduring vibrations and temperature shifts.

- Horticultural/grow lights: Copper substrate PCB designs support high-brightness LED arrays essential for grow light LED PCBs, promoting better plant growth through efficient heat dissipation.

- Stage and architectural lighting: Custom LED modules with 3535 LEDs offer precise light control and long lifespan, perfect for dynamic stage setups and architectural highlights.

- Industrial floodlights and high-bay fixtures: High power LED MCPCBs built on copper substrates provide the durability and heat spreading necessary for heavy-duty industrial environments.

For tailored lighting solutions, these PCBs combine ruggedness with high performance, making them a go-to choice for OEM 3535 LED PCBA projects that demand both efficiency and longevity. Consider checking out our range of automotive 3535 LED boards or white LED light circuit PCB boards for examples of application-specific designs.

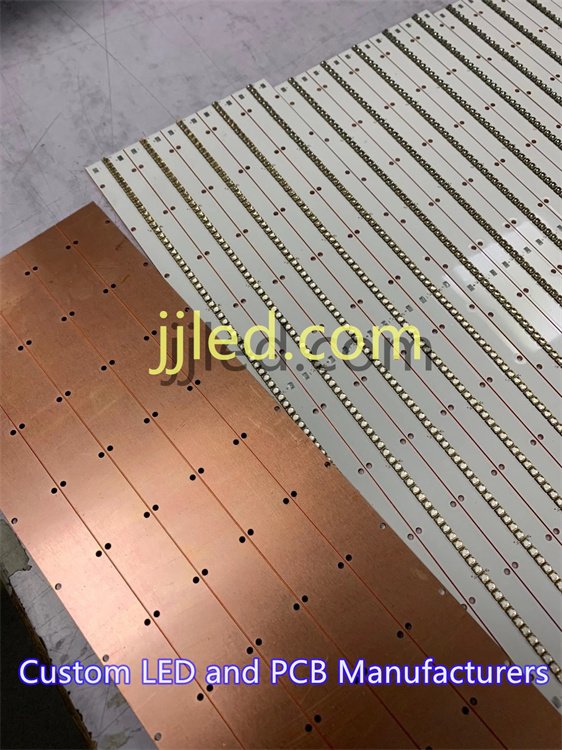

Our Expertise in Manufacturing Custom 3535 LED PCBs

We specialize in producing high-quality custom 3535 LED PCBs using advanced copper substrates. Our manufacturing process follows strict production standards to ensure excellent thermal management and electrical performance, vital for 3535 SMD LED boards. Copper substrate LED PCBs provide superior heat dissipation, which is essential for high-power LED modules.

Our customization options are flexible to meet your specific needs. Whether you require variations in size, shape, LED count, copper thickness, or surface finishes, we can tailor the PCB to your project\’s requirements. This adaptability supports a wide range of applications, from automotive 3535 LED boards to industrial grow light LED PCBs.

Quality assurance is a top priority. Each PCB undergoes rigorous testing, including thermal cycling, electrical inspections, and reliability checks. We also maintain compliance with relevant certifications to guarantee consistent performance and durability over time.

We have successfully delivered numerous projects featuring custom LED module designs and high-brightness LED circuit boards, demonstrating our capability in handling complex layouts for optimal light distribution and heat management. For a deeper look into our custom LED PCB solutions, explore our dedicated custom LED board options to see how we can bring your ideas to life.

How to Order Your Custom 3535 LED PCB

Ordering your custom 3535 LED PCB with a copper substrate is straightforward when you follow a clear process. Here’s a simple step-by-step guide to help you get started:

Submit Your Design Files

Prepare and send your design files, typically Gerber files, which detail your PCB layout and specifications. Include information about the specific 3535 LED models you plan to use, power requirements, and any desired customizations in size, shape, or LED count.

Prototype and Review

Once your design is received, a prototype will be manufactured for you to test. This stage allows you to check fit, soldering pads, thermal management, and overall performance before moving into mass production.

Confirm Order Quantity and Lead Times

Discuss minimum order quantities (MOQs), which vary based on complexity and customization. Typical lead times can range from a few weeks to a month depending on production schedules and order size.

Pricing Factors

Pricing depends on factors like PCB size, copper thickness, LED count, and any specialized finishes. Using copper substrate for your 3535 LED board provides better thermal management but might slightly influence costs compared to standard FR-4 PCBs.

Tips for Providing Specifications:

- Clearly specify the type and brand of 3535 SMD LEDs you are using (e.g., Cree or Nichia).

- Provide detailed power and current requirements to ensure the copper substrate and thermal design will handle the load.

- Include any mechanical constraints or compatibility notes with optics, drivers, or enclosures.

- If you need assistance, include design input requests or reach out to your supplier for professional guidance.

If you’re interested in custom LED module design or further PCB options, our range of factory LED PCBs for light photography can offer inspiration and solutions tailored to your project.

By following these steps, you can efficiently order a reliable, high-performance custom 3535 LED PCB tailored to your needs, leveraging the thermal and electrical advantages of copper substrate technology.