Understanding LED Module PCBs

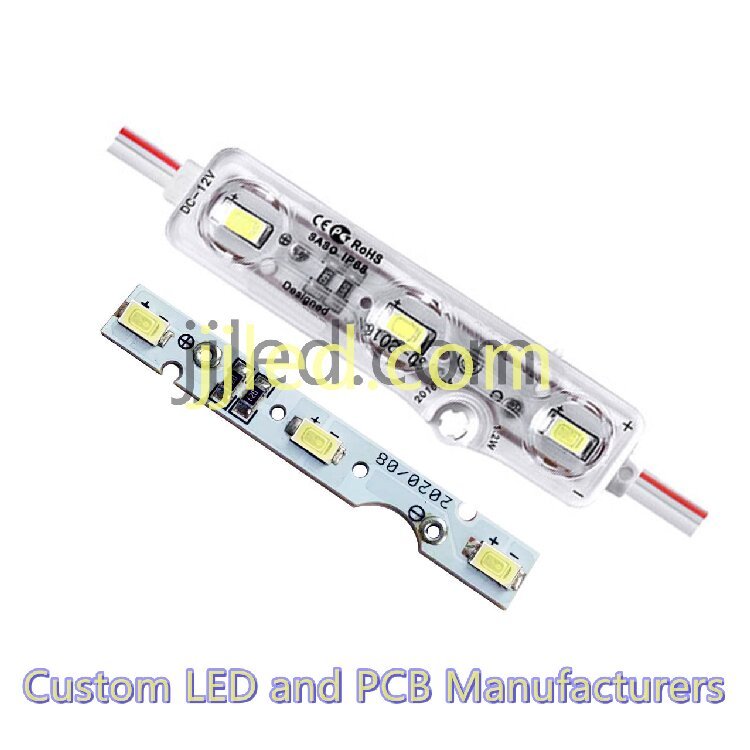

LED module PCBs are the foundation of modern lighting solutions, combining several essential components to deliver efficient, reliable light. The core parts of an LED module PCB include:

- LEDs: These are the actual light sources, typically surface-mount devices (SMD) that provide bright, energy-efficient illumination.

- Substrate: Usually made from materials like FR4 or FPCB or aluminum, the substrate supports the LEDs and helps manage heat.

- Circuit Layer: This layer connects the LEDs electrically, allowing power distribution and control signals to flow smoothly.

How LED Module PCBs Work

An LED module PCB works by providing an electrical network that powers the LEDs and regulates their operation:

- Electrical current runs through the circuit layer to the LEDs.

- Each LED emits light when energized, producing the desired brightness and color.

- Some LED modules include control elements, enabling dimming, color tuning, or dynamic lighting effects.

Evolution of LED Module PCBs

The technology behind LED module PCBs has rapidly evolved:

- Early LED boards were basic, with limited functionality and minimal colors.

- Today’s modules are advanced systems featuring custom LED modules, integrated drivers, efficient heat sinks, and versatile light outputs.

- This evolution has enabled LED module PCBs to power everything from signage to sophisticated architectural lighting, offering improved reliability and performance worldwide.

Types of LED Module PCBs

LED module PCBs come in various types, mainly classified by the materials used and their configuration to meet different performance and application needs.

Material-Based Classification

- Aluminum PCBs: The most common choice for LED modules, aluminum-based PCBs offer excellent thermal management thanks to their metal core. This helps dissipate heat effectively, extending the lifespan and maintaining efficiency of the LEDs. Many high-power LED boards depend on aluminum LED PCBs to prevent overheating. For more on this, check out our detailed guide on the advantages of aluminum LED PCBs.

- FR4 PCBs: These are standard fiberglass-based PCBs used mostly in low to medium power LED applications. They’re cost-effective but less efficient in heat dissipation compared to metal core options.

- Flexible and Rigid-Flex PCBs: Flexible LED PCBs allow for bending and shaping, making them ideal for curved or irregular surfaces. Rigid-flex combines both rigid and flexible layers, providing mechanical strength where needed alongside flexibility.

- Ceramic and Copper-Based PCBs: Used for high-performance LED modules, ceramic PCBs offer superior heat resistance and electrical insulation, supporting extreme thermal environments. Copper substrates also enhance thermal and electrical conductivity for specialized applications.

Configuration Types

- Single-Color Modules: Designed to emit one steady color, commonly used in basic lighting setups.

- Tunable White Modules: These allow adjustment of white light temperature, ideal for environments needing customizable ambiance, like offices or retail.

- Multi-Chip Modules: Incorporate multiple LED chips on one board, enabling richer color mixes or higher brightness for advanced lighting systems.

Choosing the right type depends on the project’s requirements for heat management, flexibility, durability, and light control. For custom LED module PCB options tailored to your specific design, working with an experienced manufacturer can make a big difference.

Common Colors of LED Modules and Their Applications

LED module PCBs come in a variety of colors, each suited for specific uses:

- Warm White (2700K-3000K): Perfect for residential spaces, hospitality, and ambient lighting. It creates a cozy, inviting atmosphere ideal for homes and hotels.

- Neutral White (4000K-4500K): Commonly used in offices, retail stores, and task lighting. This color balances brightness and comfort, helping productivity without harsh glare.

- Cool White (5000K-6500K): Best for industrial environments, outdoor settings, and areas requiring high visibility. Its crisp light enhances safety and detail.

- Single Colors (Red, Green, Blue, Amber): These are popular in signaling, decorative lighting, and specialty applications like indicators or accent lighting.

- Specialized Options: UV and IR LEDs serve horticulture or therapeutic purposes, while full-spectrum LED modules support plant growth and health treatments.

Choosing the right LED color ensures your project fits its environment and function perfectly. For reliable performance in white light applications, you can explore our selection of white light SMD LEDs which deliver consistent quality and efficiency.

LED Modules vs. RGB LED Modules: Features and Use Cases

When choosing LED module PCBs, understanding the difference between standard LED modules and RGB LED modules is key.

| Feature | Standard LED Modules | RGB LED Modules |

|---|---|---|

| Color Output | Fixed color (single or tunable white) | Dynamic color mixing, millions of hues |

| Efficiency | High for uniform, consistent light | Moderate, due to color mixing process |

| Control Requirements | Simple on/off or dimming | Requires RGB controller for color change (LED light controller) |

| Energy Use | Lower power consumption | Higher due to multiple color chips |

| Use Cases | Static lighting: offices, retail, home | Dynamic lighting: stage, events, displays |

For projects needing solid, reliable white or single-color lighting, standard LED modules offer excellent efficiency and simplicity. On the other hand, RGB LED modules shine when you want dynamic effects with color changes or mood lighting.

There are also RGBW and advanced variants designed to improve white light quality and create pastel shades, combining the best of both worlds for intricate lighting designs.

If you need precise control over colors or want dynamic lighting options, exploring RGB LED modules paired with controllers and dimmers can elevate your project. For fixed, cost-effective, and energy-saving options, standard LED modules remain the best choice.

Key Design Considerations for LED Module PCBs

When designing LED module PCBs, several key factors ensure optimal performance and durability.

Thermal management is crucial since LEDs generate heat that can affect lifespan and brightness. Using heat sinks and choosing the right substrate—like aluminum or metal core PCB—helps dissipate heat efficiently and keeps the module running cool.

Power options also matter: constant current drivers provide stable output and prevent overheating, whereas constant voltage drivers are simpler but need careful matching with module requirements. For more on power design, check our detailed guide on LED driver circuit design.

Waterproofing and durability determine where the module can be used. Look for IP-rated LED modules to ensure protection against dust and moisture, especially for outdoor or industrial settings.

Finally, size, shape, and mounting options are important for fitting the module into your project. Whether you need linear strips, round modules, or custom shapes, these choices impact installation and lighting effect.

Prioritizing these design aspects results in efficient, reliable LED module PCBs tailored for diverse lighting applications.

Customization Options for LED Module PCBs

Custom LED module PCBs let you tailor your lighting solution exactly how you need it. Whether it’s size, power, LED density, or color spectrum, customization ensures your project gets the perfect fit.

Tailored Features Include:

| Feature | Customization Options |

|---|---|

| Size & Shape | Small, large, linear, round, or custom designs |

| Power & Voltage | Low to high wattage, constant current or voltage |

| LED Density | Sparse to high-density layouts |

| Color Spectrum | Single color, tunable white, RGB, or full spectrum |

Benefits of Custom Solutions:

- Optimized performance for your specific use case

- Enhanced thermal management with the right substrate choice

- Improved energy efficiency based on required brightness and color

- Better integration into existing fixtures or systems

Custom LED PCB Production Process:

- Design Consultation – Discuss your exact needs and applications

- Prototype Development – Create samples to test layout and performance

- Production & Testing – Manufacture the final batch meeting quality standards

Choosing a custom LED module PCB means getting a product perfectly aligned with your technical and design goals. Working with experienced manufacturers also unlocks advanced options like optimized heat sinks, complex circuitry, or specialty LEDs for horticulture or signage.

For tailored solutions that maximize reliability and efficiency, custom LED module PCBs are the way forward.

Applications of LED Module PCBs

LED module PCBs are incredibly versatile and find use across many industries due to their efficiency, durability, and ease of integration. Here are some of the main applications where our LED module PCBs excel:

- Signage and channel letters: These PCBs are perfect for brightly lighting advertising signs and channel letters, providing uniform illumination and long-lasting performance. You can also check specialized solutions like signage LED modules designed for this purpose.

- Architectural and facade lighting: LED modules help highlight building exteriors and enhance architectural features with customizable colors and brightness, adding both aesthetics and energy efficiency.

- Automotive and vehicle interiors: From dashboard lighting to ambient cabin lights and tail lights, automotive-grade LED PCBs deliver reliability under tough conditions. Explore more on high-quality tail light LED boards ideal for automotive use.

- Horticulture and grow lights: Specialized horticulture LED PCBs support plant growth by offering tailored light spectra that promote photosynthesis, improving crop yield in indoor farming environments.

- Commercial fixtures: This includes troffers, downlights, and high bays used in office spaces, warehouses, and retail stores where uniform, high-efficiency lighting is critical.

- Emerging uses: LED module PCBs are expanding into displays, backlighting for screens, and smart lighting systems with advanced controls for dynamic environments.

With a wide range of LED module options—including aluminum cores for heat management and flexible PCBs for unique shapes—these applications can meet diverse lighting needs with reliable, customized solutions.

Selecting the Right LED Module PCB Supplier

Choosing the right LED module PCB supplier is crucial for your project’s success. Here are some important factors to consider:

- Quality Certifications: Look for suppliers with recognized quality standards like ISO or RoHS compliance to ensure reliable, safe LED PCBs.

- Customization Capabilities: A good manufacturer should offer custom LED module PCB designs tailored to your size, power, and LED density needs.

- Lead Times: Fast turnaround matters. Check their production speeds to match your project deadlines without sacrificing quality.

Partnering with a dedicated LED module PCB manufacturer brings advantages like expert guidance on thermal management LED design, access to advanced materials like aluminum LED PCBs, and support through prototyping to full-scale production. This collaboration helps you achieve consistent performance and durability, whether you need flexible LED PCBs for dynamic installations or high-power, waterproof LED modules for industrial use.

For more on flexible designs, check out our LED flexible PCB with LEDs page, where customization meets performance.

Finding the right supplier ensures you get high-quality, tailored LED module PCBs that fit your application and industry demands perfectly.