Understanding LED PCBs: Types and Key Requirements

When it comes to LED PCB fabrication, choosing the right type of circuit board is crucial. The most common types include:

| PCB Type | Key Features | Typical Use |

|---|---|---|

| Aluminum Core (MCPCB) | Excellent heat dissipation, durable, cost-effective | High-power LED lighting |

| FR-4 | Standard PCB material, lower cost | Low to mid-power LED applications |

| Flexible (Polyimide) | Bendable, lightweight | Wearables, LED strips |

| Copper Base | High conductivity, sturdy | Specialized thermal needs |

| Ceramic | Superior heat resistance, stable | High-end, high-reliability LEDs |

| Hybrid | Combines materials for tailored performance | Custom LED solutions |

Why Aluminum Core Leads in High-Power LEDs

For high-power LED board manufacturing, aluminum core PCBs dominate because of:

- Thermal conductivity: Aluminum efficiently draws heat away from LEDs, ensuring longer life and stable output.

- Cost-efficiency: Aluminum cores balance performance and price better than ceramics.

- Durability: They withstand vibration and mechanical stress, ideal for harsh environments.

Essential LED Application Needs

LED applications demand more than just basic circuit boards. Key requirements include:

- Superior heat transfer: Effective cooling prevents premature LED failure.

- Reflectivity: White solder masks enhance light reflection, boosting efficiency.

- Vibration resistance: Ensures the PCB holds up in moving or industrial settings.

- Compact design: Space-saving layouts for integrated lighting solutions.

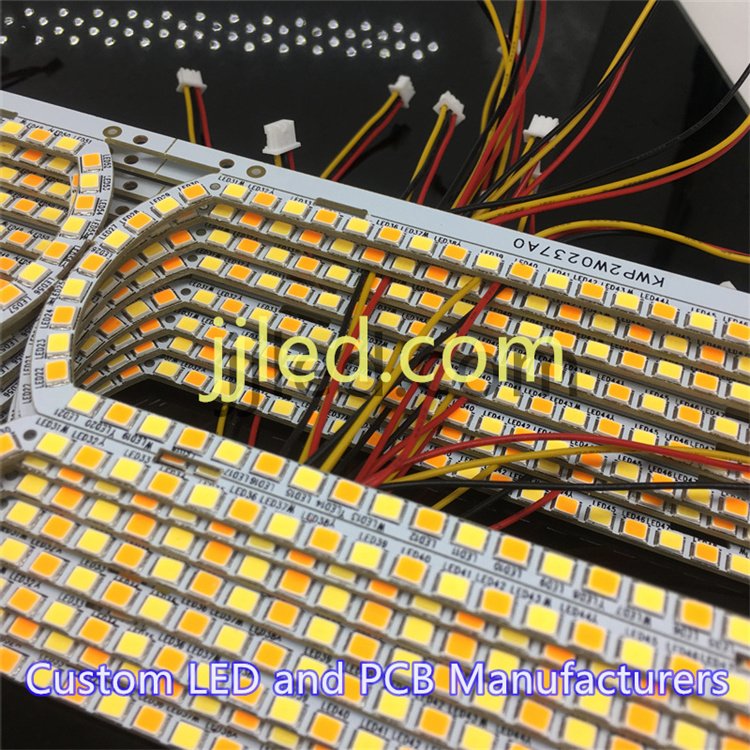

Mounting Approaches: SMD vs. COB

Mounting style impacts PCB design and fabrication:

| Mounting Type | Description | Fabrication Impact |

|---|---|---|

| SMD (Surface Mount Device) | Individual LEDs placed on PCB surface | Requires precise surface finishes and soldering |

| COB (Chip On Board) | LED chips directly bonded to PCB | Needs excellent thermal pathways and smooth surfaces |

Each method demands different manufacturing precision and materials, affecting how LED PCBs are fabricated.

Choosing the right LED PCB type combined with understanding application demands and mounting methods is foundational for high-quality LED PCB manufacturing. This sets the stage for reliable, efficient, and customized LED lighting solutions.

Core Materials in LED PCB Fabrication

Choosing the right materials is crucial for effective LED PCB manufacturing. Aluminum is the go-to core material because it offers excellent thermal performance, making it ideal for high-power LED boards needing rapid heat dissipation. Compared to standard FR-4, aluminum’s thermal conductivity is significantly higher, helping to prevent overheating and boost LED lifespan. Flexible polyimide substrates provide versatility for curved or irregular LED designs but generally have lower heat transfer capabilities. Ceramic substrates, while more expensive, excel in thermal stability and electrical insulation, making them perfect for demanding LED lighting applications where heat and reliability matter most.

The dielectric layer plays a key role by electrically insulating the copper layer from the metal core while still allowing efficient heat flow. Its thickness and composition directly impact the LED PCB’s ability to spread heat evenly without compromising electrical performance.

Copper thickness is another factor to consider. Thicker copper layers improve current capacity and heat spreading but increase costs and can affect flexibility. For LED PCBs, balancing copper weight typically falls between 1oz to 3oz, depending on power requirements.

Surface finishes such as ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), and immersion tin each influence solderability and reflectivity. ENIG is widely favored in LED PCB fabrication due to its excellent solder joint reliability and corrosion resistance. Using a white solder mask enhances reflectivity, optimizing light output—parameters that directly affect LED performance.

For a wide range of LED designs, including custom aluminum LED PCBs or flexible LED PCBs, carefully selecting these core materials ensures optimal heat management and reliability throughout manufacturing. To explore custom options tailored for LED lighting, you can review our detailed offerings on custom high-power aluminum LED PCB solutions and flexible LED PCB with LEDs.

Step-by-Step LED PCB Fabrication Process

Manufacturing a reliable LED PCB takes a carefully planned, precise process tailored to LED-specific needs. It all starts with a detailed design and engineering review. Here, Design for Manufacturability (DFM) analysis checks thermal paths, component placement, and overall build feasibility to make sure heat spreads efficiently and parts fit perfectly.

Next up is material preparation and lamination, where special attention goes to bonding the metal core—typically aluminum—for optimal heat dissipation. This metal core PCB for LEDs plays a crucial role in managing the high thermal demands of LED boards.

After lamination, drilling and plating handle the creation of vias, which must be precise to withstand the heat generated during operation. These plated through-holes ensure effective electrical connectivity and thermal flow between layers.

Once drilling is done, imaging, etching, and stripping form the copper traces that define the circuit. Accurate etching is key to maintaining electrical performance while avoiding shorts or breaks.

The solder mask application follows, typically using a white solder mask that enhances light reflection—a must for LED lighting PCB production. Silkscreen printing then adds component references and markings, aiding assembly accuracy.

Surface finishes like ENIG or OSP come next, picked based on their influence on solderability and reflectivity. These finishes protect the copper and ensure strong bonds with soldered parts.

Routing or V-scoring separates individual PCBs efficiently during mass production without damaging circuits. Finally, thorough electrical testing, thermal cycling, and quality inspections kick in. Automated Optical Inspection (AOI), X-ray, and functional testing verify that each LED PCB meets performance and reliability standards.

For more on the design specifics and material prep, check out our detailed LED light circuit board design resource.

This stepwise approach guarantees LED PCBs with excellent thermal management and long-term durability, essential for today’s high-power LED applications.

Thermal Management Techniques in LED PCB Production

Managing heat effectively is crucial in LED PCB manufacturing to ensure long-lasting performance and reliability. One of the main strategies is using thicker copper layers, which help spread heat away from high-power LED chips quickly and efficiently. Along with this, designers often incorporate thermal vias—small holes filled or plated with metal—that connect the LED’s heat-generating areas to the aluminum or metal core base, dramatically improving heat dissipation.

The choice and optimization of the aluminum base itself play a vital role. Aluminum’s natural high thermal conductivity combined with proper bonding techniques ensures that heat moves away from critical components smoothly, preventing hotspots that can cause LED failure.

Common issues in LED PCB production related to heat include overheating and delamination (where layers separate due to thermal stress). To prevent these, manufacturers control thermal expansion by selecting suitable substrates and dielectrics and carefully managing the layer stack-up. In addition, surface finishes that support heat conductivity and mechanical strength add another layer of protection.

Advanced thermal simulations and testing are increasingly integrated into the fabrication process. These tools predict potential cooling problems before production, allowing for design adjustments that improve heat flow and overall PCB durability. Techniques like thermal cycling tests verify that the boards can handle repeated temperature changes without degradation, ensuring a robust metal core PCB for LEDs or other custom LED circuit boards.

For detailed designs focused on optimizing heat management, exploring specialized products like round aluminum PCB LED boards can provide insights into advanced aluminum core designs built for high-power LED applications.

Assembly Considerations for LED PCBs

When it comes to assembling LED PCBs, understanding the differences between SMT (Surface Mount Technology) and COB (Chip on Board) processes is crucial. SMT assembly involves mounting individual LED chips or components directly onto the PCB pads, which is excellent for high-volume, precise placement and supports complex circuits like SMD LED PCB assembly. COB assembly, on the other hand, mounts bare LED chips directly onto the substrate, offering better thermal performance and light output for high-power LED boards but requires more specialized handling.

In both approaches, sourcing high-quality components plays a vital role in ensuring LED longevity and consistent performance. Precise placement accuracy is essential—misaligned LEDs can affect light distribution and reliability. Reflow profiling must be carefully controlled to balance solder joint integrity without damaging sensitive LEDs, especially when working with flexible or aluminum LED PCBs.

Testing protocols are another key step in assembly. Burn-in tests catch early failures by running LEDs under rated conditions for specific periods. Lumen output measurements ensure brightness matches design goals. Color consistency checks prevent shifts in hue that can impact visual appeal, while environmental stress screening simulates temperature changes, vibration, and humidity to certify durability.

Choosing the right assembly method and following strict quality steps leads to LED circuit boards that perform reliably in demanding lighting applications. For a deeper look into assembly options, exploring specialized LED PCB assembly services can provide valuable insights.

Advantages of Partnering with a Dedicated LED PCB Manufacturer in China

Working with a specialized LED PCB manufacturer in China offers clear cost benefits without sacrificing quality. Chinese suppliers leverage advanced manufacturing setups and lean processes to keep prices competitive, whether you\’re ordering small prototype runs or scaling up to full mass production. This flexibility is especially valuable for LED PCBs, where demand can shift quickly.

Customization is another big advantage. From special dielectrics to heavy copper layers and flex-rigid hybrids, many China LED PCB manufacturers can tailor your board to meet the precise thermal and mechanical needs of your LED application. This level of customization helps optimize performance, especially for high-power LED boards or unique designs.

Chinese LED PCB suppliers pride themselves on fast turnaround times and tight supply chain management, which minimizes delays and keeps your projects on track. They also ensure compliance with major standards like RoHS and UL, giving you peace of mind about product safety and environmental impact.

What really sets China LED PCB manufacturers apart is their full-service approach. Beyond fabrication, they often offer engineering support to review your design’s manufacturability and thermal management, boosting reliability and efficiency. Their proven track record with LED-specific circuits means you get a partner who understands the unique challenges of LED lighting PCB production from start to finish.

For a closer look at high-quality solutions, check out the variety of custom LED circuit boards and high-CRI LED PCB boards available from trusted China suppliers, which demonstrate the benefits of experienced manufacturing tailored to LED needs.

How to Select and Work with an LED PCB Supplier

Choosing the right LED PCB fabrication manufacturer is crucial for a smooth project and quality results. Here are some key points to consider:

Key Evaluation Criteria

- Experience in LED Projects: Look for manufacturers who specialize in LED PCB thermal management and high-power LED board production. Their deep understanding ensures they handle the unique challenges of LED lighting PCB production.

- Certifications and Compliance: Confirm they meet industry standards like RoHS and UL to guarantee safety and environmental compliance.

- Advanced Equipment: Ensure the supplier uses modern fabrication technology capable of precise drilling, plating, and surface finishes tailored for LED PCBs.

- Lead Times and MOQ Flexibility: Check their turnaround times and minimum order quantities, especially important if you’re scaling from prototypes to mass production.

- Customization Options: Verify they can handle custom LED circuit boards including flexible LED PCB manufacturing or metal core PCB for LEDs.

What to Provide for Accurate Quotes

- Detailed Gerber Files: Include clear layer details and specifications to avoid miscommunication.

- Comprehensive Specs: Outline materials (like aluminum LED PCB), copper thickness, and surface finish preferences.

- Volume Estimates: Sharing your estimated order quantity helps suppliers suggest optimized pricing and production schedules.

Tips for Successful Collaboration

- Clear Specifications: Detailed documentation speeds up manufacturing and reduces errors.

- Early DFM Feedback: Engage the supplier in design for manufacturability (DFM) consultations early to optimize your LED PCB design.

- Iterative Prototyping: Start with prototypes to test thermal performance and assembly before full-scale production.

Common Pitfalls to Avoid

- Unclear Design Files: Incomplete or vague Gerber files lead to delays and costly revisions.

- Ignoring Thermal Needs: Overlooking heat dissipation requirements can cause failures in high-power LED boards.

- Skipping Supplier Checks: Failing to vet the manufacturer’s past work or certifications might risk your product’s quality and reliability.

Partnering with a trusted China LED PCB supplier can streamline production, offering cost efficiencies without quality trade-offs. For a detailed look at the production approach, explore how LED PCBs are manufactured on trusted industry sites. This ensures you’re working with a team that understands every nuance of LED strip PCB manufacturing and custom LED PCB assembly.