If you’re exploring ways to achieve smooth, flicker-free lighting with precise control, a PWM LED controller is exactly what you need. Whether you’re customizing LED strips for home lighting, designing complex RGB setups, or building professional-grade dimming solutions, understanding pulse width modulation (PWM) is crucial. In this guide, you’ll discover why PWM is the go-to method for efficient, high-performance LED dimming and how the right PWM LED controller can elevate your projects—from simple DIY builds to advanced installations. Ready to master the art of LED control? Let’s get started!

Understanding PWM LED Dimming

When it comes to controlling LED brightness, PWM dimming LED is the most efficient method widely used today. But what exactly is PWM and why does it matter?

How PWM Works: Pulse Width Modulation Explained

PWM, or Pulse Width Modulation, controls LED brightness by rapidly switching the LED on and off at a fixed frequency. Instead of lowering the voltage, it changes the duty cycle—the ratio of ON time to the total cycle time—making the LED appear dimmer or brighter.

- 100% duty cycle = LED fully ON

- 50% duty cycle = LED half as bright (LED ON and OFF equally)

- 10% duty cycle = LED dimmed low

This switching happens so fast (usually thousands of times per second) that our eyes see a steady light rather than flicker.

PWM vs. Analog Dimming: Key Differences, Pros, and Cons

| Feature | PWM Dimming | Analog Dimming |

|---|---|---|

| Brightness Control | Duty cycle modulation | Reducing voltage/current |

| Efficiency | Very high (no power loss) | Can cause heat and reduce lifetime |

| Color Accuracy | Maintains consistent color | Color shifts at low voltage levels |

| Flicker Risk | Depends on PWM frequency | Usually flicker-free but less stable |

| Complexity | Requires PWM driver | Simpler but less effective |

Why choose PWM? It’s ideal when you want energy efficiency, precise brightness control, and consistent LED color stability over time.

PWM vs. Other Dimming Methods

Besides analog dimming, you might come across other methods like CCR (Constant Current Reduction), 0-10V, or TRIAC dimming.

| Method | How It Works | Ideal For | Pros | Cons |

|---|---|---|---|---|

| PWM | Switches LED rapidly ON/OFF | LED strips, modules, and arrays | Efficient, flicker-free* | Requires proper frequency |

| CCR | Lowers current gradually | Some LED types with constant current drivers | Simple, smooth dimming | Can overheat LEDs |

| 0-10V Dimming | Analog voltage control | Commercial lighting systems | Easy integration | Needs dedicated wiring |

| TRIAC Dimming | Phase-cut line voltage control | Household LED bulbs & fixtures | Works with AC mains | Not optimal for LED strips |

*Note: PWM’s flicker-free status depends on the PWM frequency setting.

Importance of PWM Frequency: Avoiding Flicker

A common concern: Why does LED flicker matter?

- Flicker can cause eye strain, headaches, and poor video/photography results.

- For broadcasts or photography, flicker shows up as bands or strobe effects.

Ideal PWM frequency ranges:

| Application | Recommended PWM Frequency |

|---|---|

| General lighting | 500 Hz – 1 kHz |

| Flicker-sensitive uses | > 10 kHz |

| Video/studio lighting | 20 kHz or higher (ultrasonic) |

Higher frequencies help eliminate perceptible flicker, ensuring flicker-free LED dimming ideal for modern applications.

In : For reliable and smooth brightness control, choosing the right PWM LED controller with an appropriate frequency and understanding its advantages over analog and other dimming methods can transform your LED projects—whether for home, automotive, or commercial use.

Key Features to Look for in a PWM LED Controller

When choosing a PWM LED controller, focus on features that match your lighting project’s needs. Here’s a quick overview of what to consider:

| Feature | What to Expect |

|---|---|

| Channel Options | Single-color, RGB, RGBW (RGB + White), CCT (tunable white), or multi-zone control for complex setups. |

| Voltage & Current | Most common are 12V or 24V controllers. Check if it can handle high current for powerful LED arrays. |

| Control Interfaces | Options include RF remote, Wi-Fi/Bluetooth apps, DMX for professional use, wall-mounted units, or physical knobs/sliders. |

| Advanced Capabilities | High-frequency PWM (>1kHz) to avoid flicker, programmable lighting effects, and built-in thermal protection for safety. |

| LED Type Compatibility | Supports LED strips, modules, COB (chip on board), and high-power LED arrays for versatility. |

Why These Matter

- Channel Options: RGBW and CCT controllers provide richer color tuning and white balance control, essential for professional and home setups.

- Voltage and Current: Pick a controller rated correctly for your LED power requirements to ensure stable operation and avoid overheating.

- Control Interfaces: Wireless control via apps or remotes offers convenience. DMX interface suits stage or large architectural installs.

- Advanced Features: High-frequency PWM reduces flicker, important for video and photography environments.

- Compatibility: Ensure your controller matches the LED type—whether flexible strips or rigid high-power modules.

For detailed insights on how PWM differs from other dimming types and choosing the right driver, check our guide on PWM LED dimmer vs. constant current dimmer for LED lights. Also, explore options for multi-channel control in our RGBW LED strip controller overview.

Choosing a PWM LED controller with these features will ensure you get smooth, flicker-free dimming, flexible control, and compatibility with your LED lighting project.

Types of PWM LED Controllers

When choosing a PWM LED controller, it helps to know the main types available. Each suits different projects, from simple setups to complex industrial systems.

| Controller Type | Description | Typical Use |

|---|---|---|

| Basic Inline Dimmers | Simple devices for single-color LED strips. Adjust brightness with minimal setup. | Home DIY, accent lighting |

| Multi-Channel Controllers | Control RGB, RGBW, or tunable white LEDs across multiple channels for color mixing and effects. | Mood lighting, decorative lighting |

| Smart/Wireless Controllers | Use protocols like Tuya, Zigbee, or Bluetooth Mesh for app or voice-controlled lighting. | Smart homes, IoT lighting control |

| Professional/Industrial Controllers | Support DMX512, DALI, or other industrial protocols for precise, large-scale lighting networks. | Stage lighting, architectural, commercial |

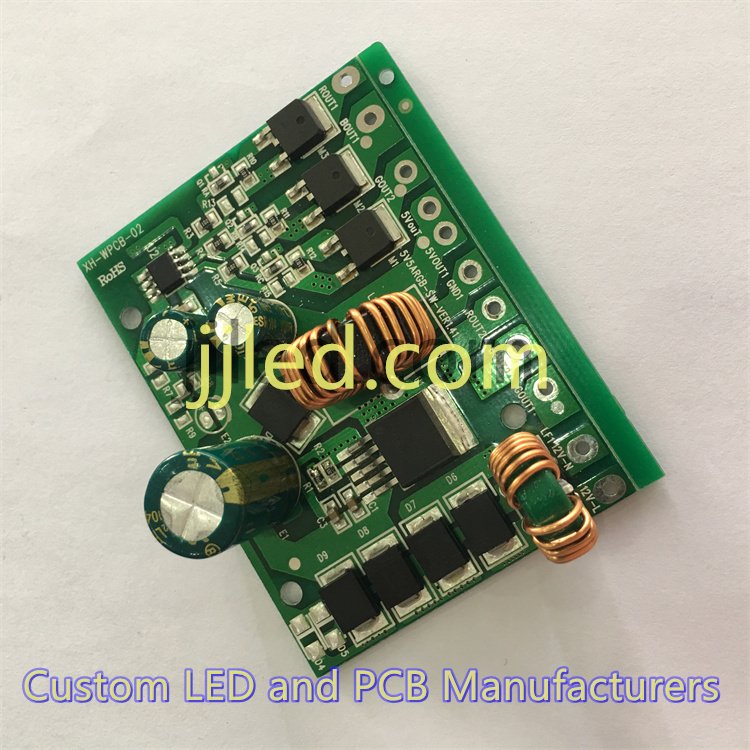

| Custom PCB-Based Controllers | Tailored designs for OEMs or specialized applications, offering flexibility in channel count, power, and protocols. | Automotive, IoT devices, unique projects |

Basic Inline Dimmers are perfect when you want a quick and cost-effective way to dim a single-color LED strip without extra features.

For projects needing color control, Multi-Channel Controllers let you manage RGB or RGBW lighting effortlessly, ideal for dynamic color effects or tunable white setups.

If convenience and integration with existing smart systems matter, Smart/Wireless Controllers bring easy remote access and automation. These controllers often support popular apps and voice assistants.

For demanding environments, Professional/Industrial Controllers come with standards like DMX512 and DALI, ensuring compatibility with professional lighting and control systems.

Finally, if your project requires something specific — like certain power ratings, protocols, or form factors — Custom PCB-Based Controllers offer bespoke solutions. Custom designs help meet unique needs, from automotive LED setups to high-end IoT lighting.

Want to learn more about custom designs? Check out our detailed assembly options for custom LED control PCB boards.

Selecting the right controller type ensures your LED system performs well and fits your control preferences perfectly.

Top PWM LED Controllers on the Market in 2026

Finding the right PWM LED controller in 2026 means balancing cost, features, and your specific lighting needs. Here’s a quick overview of popular categories in today’s market:

| Category | Features | Ideal For | Example Use Cases |

|---|---|---|---|

| Best Budget Options | Simple PWM dimming, basic single/multi-channel, RF remote or knob control | Home setups, DIY projects | Mood lighting, LED strip dimmers |

| Premium High-Frequency Models | >1kHz PWM frequency, flicker-free output, stable color control | Video, photography, studio lighting | Flicker-free continuous lighting demands |

| Smart Integrated Controllers | Wi-Fi/Bluetooth, app control, voice assistant compatibility | Smart homes, IoT integration | Tunable white, RGBW LED strips for automation |

| High-Power Commercial Solutions | High current/voltage support, multi-zone, DMX/DALI compatibility | Architectural lighting, signage | Large installations, multi-zone color zones |

Best Budget Options for Home/DIY Use

Budget-friendly PWM LED controllers often support 12V or 24V LED strips with simple interfaces like RF remotes or knobs. They’re perfect for bedroom lighting, accent lights, and small DIY projects. These controllers deliver reliable PWM dimming LED performance without breaking the bank.

Premium High-Frequency Models for Video/Studio Lighting

For professional lighting, premium controllers use high-frequency PWM (above 1kHz) to ensure flicker-free LED dimming crucial in video and photography setups. These models maintain color precision across dimming levels — a must for studios.

Smart Integrated Controllers for Home Automation

Smart controllers blend convenience with functionality. They support app control via Wi-Fi or Bluetooth, and many integrate with platforms like Alexa or Google Home. These units often handle RGB, RGBW, and tunable white LEDs, making them great for adaptive lighting systems. Check out options optimized for tunable white LED controller applications like these LED light circuit board designs.

High-Power Solutions for Commercial/Architectural Installations

Heavy-duty PWM controllers support high-current LED arrays and multi-zone setups, frequently with DMX or DALI interfaces for professional lighting control. They excel in large-scale signage, architectural lighting, and automotive projects, where durability and precise control are key. Our tail light LED boards showcase how rugged, high-power controllers work in real-world applications.

Choosing the right PWM LED controller depends on your system’s size, complexity, and control preferences. Whether you\’re outfitting a home theater or managing commercial displays, the 2026 market has a tailored solution just for you.

Custom PWM LED Controller PCBs: Tailored Solutions

Custom PWM LED controller PCBs offer precise control tailored to your exact needs. Whether you\’re managing multi-zone LED lighting, high-power arrays, or integrating smart controls, a custom board can deliver efficiency and compactness that off-the-shelf products can’t match.

Advantages of Custom PCB Designs

- Compact Size: Fit complex circuitry into a small form, ideal for tight spaces.

- Specific Features: Integrate exact channel counts, control types, and protection functions.

- Seamless Integration: Easily combine with other electronics or embedded systems for better performance.

Common Customizations

| Feature | Options | Benefits |

|---|---|---|

| Channel Count | Single-color, RGB, RGBW, CCT, Multi-zone | Precise lighting control |

| Protocol Support | DMX512, DALI, Wi-Fi, Bluetooth, RF | Compatibility with your system |

| Power Handling | 12V, 24V, High-power (>5A per channel) | Safe operation with powerful LEDs |

| Enclosures | Plastic, metal, customized designs | Protection & durability |

Why Choose a Specialized Manufacturer?

- Expertise in LED Electronics ensures optimal layout and wiring to prevent issues like flicker or interference.

- Quality Component Selection guarantees long-lasting performance and thermal stability.

- EMC Compliance helps avoid electromagnetic interference, essential for reliable dimming and communication.

Design Considerations

- Thermal Management: Use heatsinks or thermal vias to prevent overheating of high-power LEDs and drivers.

- Component Selection: Choose PWM drivers and MOSFETs rated for expected load and frequency.

- EMC Compliance: Shield and filter the PCB design to minimize noise, improving flicker-free LED dimming.

Real-World Applications

Custom PWM controller PCBs are widely used in:

- Automotive Lighting: For smooth dimming and dynamic effects in headlights and interior lights.

- Signage and Displays: To ensure uniform brightness and color accuracy in large-scale LED signs.

- IoT Devices: Enabling smart LED control via wireless protocols in connected environments.

For detailed insights on PCB design tailored for LED applications, check out our resources on design considerations for LED circuit boards and custom LED board manufacturing. These pages cover how specific PCB features impact PWM dimming and overall LED controller performance.

Installation and Wiring Guide for PWM LED Controllers

Setting up your PWM LED controller correctly is key to getting smooth, flicker-free LED dimming and reliable performance. Whether you’re working with simple single-color strips or a multi-channel RGB/RGBW system, following these steps will make installation straightforward.

Step-by-Step Setup for Common Configurations

- Connect the Power Supply: Start by matching the voltage rating of your LED controller—usually 12V or 24V—to a compatible constant voltage power supply. Power supplies must handle the total wattage of your LED strips or modules.

- Wire the LED Load: Connect your LED strips (such as 2835 LED strips) or other LED modules to the controller outputs. Make sure polarity (+ and –) is correctly aligned to prevent damage.

- Choose the Control Interface: Depending on your model, connect your control device such as an RF remote, Wi-Fi app, or DMX controller. Properly pair devices before powering on.

- Test and Adjust: Power up the system and test dimming, color changes, or effects. Adjust settings to achieve flicker free LED dimming and smooth transitions.

Power Supply Matching and Safety Tips

- Check Current Ratings: Ensure your power supply’s current capacity exceeds the total current drawn. Underpowered supplies cause voltage drops, leading to dim LEDs or flicker.

- Use Proper Wire Gauge: Use thicker wires for longer runs to reduce voltage loss. This is especially important for multi-zone or large installations.

- Grounding and Isolation: Properly ground the system for safety and noise reduction. Avoid running power wires alongside high voltage AC cables which may cause interference.

- Fuse Protection: Add inline fuses or circuit breakers to protect the controller and LEDs from short circuits or overloads.

Troubleshooting Common Issues

- Flicker: Usually caused by low PWM frequency or unstable power supply. Upgrade to a high frequency PWM controller (>1kHz) for flicker-free LED dimming.

- Overheating: Check if the controller is rated for your LED load. Use adequate heat sinks or ventilation for high-power LED arrays.

- Color Shift: Often due to voltage drops, faulty wiring, or mismatched LED types. Use consistent LED batches and verify wiring carefully.

Best Practices for Long Runs and Multi-Zone Systems

- Signal Boosters: For long LED runs or multi-zone control, use signal repeaters or amplifiers to maintain uniform brightness and color.

- Divide Loads: Split large installations into zones controlled by dedicated PWM LED controllers for fine-tuned dimming and effects.

- Plan Wiring Routes: Keep cable runs short where possible and group similar signals together to avoid electromagnetic interference.

By following these guidelines, your PWM LED controller setup will deliver consistent brightness, color, and smooth dimming across your project. For extra reliability, consider pairing your controller with quality LED components like the [2835 SMD LED chip] that ensure steady performance and longer lifespan.

Applications and Project Ideas for PWM LED Controllers

PWM LED controllers are incredibly versatile, making them a go-to solution across many lighting projects and industries. Here’s a quick overview of where you can put these controllers to the best use:

Home and Architectural Lighting

Whether you\’re aiming for cozy mood lighting or sophisticated architectural highlights, PWM dimming LED controllers let you adjust brightness seamlessly. They work perfectly with LED strips and modules to create smooth, flicker-free lighting scenes for living rooms, kitchens, or outdoor facades. Using a smart LED dimmer with Wi-Fi or Bluetooth control adds convenience for modern homes. For tailored solutions, check out custom LED driver PCBs that fit home system requirements efficiently.

Automotive and Vehicle Customization

Customizing vehicle lighting—like accent lights, underglows, or interior ambient setups—benefits greatly from pulse width modulation dimmers. These controllers offer precise brightness control without heat build-up, ensuring durable lighting that won\’t interfere with vehicle electronics. PWM LED controllers help create high-quality, flicker-free effects that enhance style and visibility on the road. Plus, compact custom LED driver PCBs fit well in automotive environments where space is limited.

Stage, Entertainment, and Digital Signage

In entertainment venues and digital signage, vibrant, multi-channel LED controllers are essential. RGB and RGBW PWM LED controllers enable dynamic color changes, programmable effects, and color mixing to make stages or advertising displays stand out. High-frequency PWM controllers prevent flicker during video or photography shoots, ensuring crisp visuals under all lighting conditions. DMX-compatible PWM LED controllers are often the professional choice here.

DIY Projects: Mood Lighting, Aquariums, Wearables

DIY enthusiasts love the flexibility of PWM LED controllers for projects like mood lighting setups, aquarium illumination, and wearable tech. They allow fine-tuned brightness and color adjustments, enhancing ambiance and functionality. For example, aquarium lighting needs tunable white LED controllers to mimic natural daylight cycles, promoting healthy aquatic life. Compact, custom PWM LED controller PCBs make integration easy for wearable devices or small-scale builds.

For more about LED strip solutions, explore our detailed guides on 2835 LED light PCB boards to find components optimized for your projects.

No matter your application, choosing the right PWM LED controller ensures you get smooth, efficient, and reliable lighting control tailored to your needs.

Buying Guide: How to Choose the Right PWM LED Controller

Selecting the right PWM LED controller can make or break your lighting project. To help you pick the best fit, let\’s break down the essentials.

Assessing Your Project Needs

Start by figuring out what your setup requires:

| Criteria | What to Consider |

|---|---|

| Power | Total wattage, voltage (usually 12V or 24V), current limits |

| Channels | Single-color, RGB, RGBW, CCT, or multi-zone control? |

| Control Type | RF remote, Wi-Fi/Bluetooth app, DMX, wired knob, wall-mounted |

Knowing these upfront helps avoid buying a controller that\’s either underpowered or overly complex.

Budget vs. Performance Trade-Offs

- Budget models are great for simple setups like single-color LED strips but might lack advanced features or high-frequency PWM.

- Mid-range controllers offer color control and decent app integration, balancing cost with convenience.

- Premium options deliver high-frequency PWM for flicker-free dimming—ideal for video or professional lighting—and advanced programmability.

Think about what features matter most. If flicker-free output or smart home integration is essential, invest accordingly.

Where to Buy: Reliable Sources and What to Avoid

- Purchase from established manufacturers or suppliers specialized in LED controllers to ensure quality and warranty.

- Be cautious with generic no-brand controllers, especially if specs are vague or prices seem too low.

- Look for controllers with clear datasheets and tech support.

For trusted, feature-rich options, explore detailed LED driver designs and advanced controllers that match your needs, like those showcased in our LED driver circuit design guide.

Future-Proofing: Trends in Smart and High-Frequency Controllers

The LED lighting scene is evolving fast:

- Smart controllers with Wi-Fi, Zigbee, or Bluetooth mesh are becoming the standard for easy integration with home automation.

- High-frequency PWM controllers (>1kHz) reduce flicker that’s visible to humans and on camera, crucial for modern lighting environments.

- Expect better thermal management and programmable effects in next-gen controllers too.

Choosing a controller that supports these features means your setup stays current longer, avoiding costly upgrades.

In , align your PWM LED dimmer choice with your power and channel requirements, balance your budget against needed features, buy from trusted suppliers, and pick a device ready for tomorrow’s lighting tech to get the most out of your investment.