Introduction to RGBW LED PCBs

RGBW LED technology has evolved significantly from traditional RGB systems by adding a dedicated white channel alongside red, green, and blue diodes. This advancement allows for pure, high-quality white light that standard RGB LEDs simply cannot achieve. The inclusion of a white LED improves color rendering, enhances brightness, and offers greater energy efficiency—features essential for modern lighting applications such as architectural illumination, smart homes, and entertainment environments.

The role of the PCB in an RGBW LED system is crucial. A well-designed RGBW LED PCB ensures stable power distribution, effective thermal management, and precise control across all four color channels. This foundation is vital for achieving reliable, high-performance lighting with consistent color output and longevity.

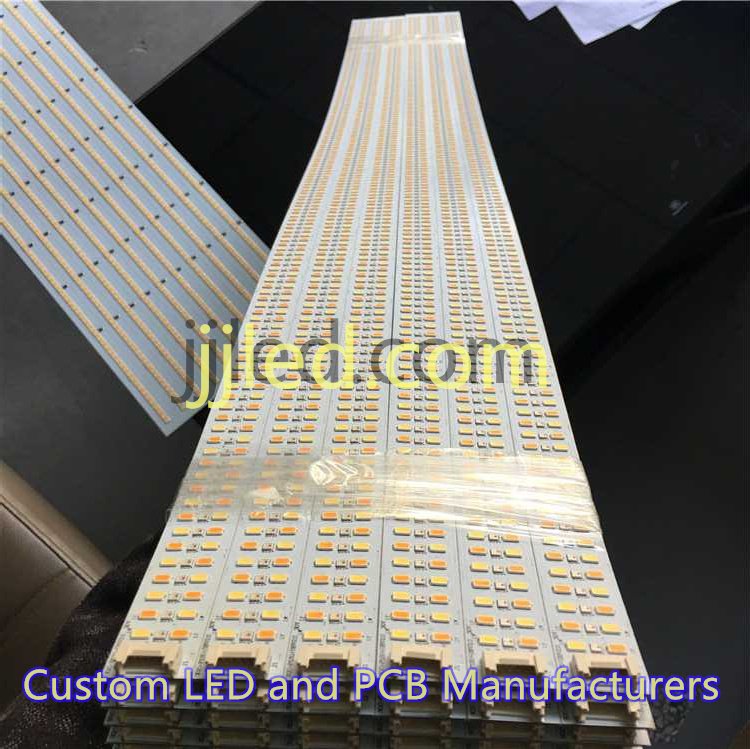

As a leading RGBW assembly manufacturer, we specialize in custom RGBW PCB design tailored to specific project needs. From flexible strips to rigid boards and addressable pixel arrays, our custom RGBW LED PCBs unlock creative freedom and maximize lighting efficiency for diverse applications.

Understanding RGBW LEDs: Basics and Advantages

RGBW LEDs combine four separate diodes—Red, Green, Blue, and White—into a single chip, offering much more than the typical RGB setup. Adding a dedicated white channel means these LEDs produce pure white light without relying on color mixing, resulting in cleaner whites and enhanced lighting quality.

The major benefits of RGBW LEDs over standard RGB include:

- Pure white light with high color accuracy (CRI over 90), essential for applications needing true color rendering

- Improved color saturation and a broader color gamut for richer visuals

- Increased energy efficiency since the white channel reduces the need to combine RGB elements to create white

- Flexibility in lighting design, allowing smooth transitions between vibrant colors and natural whites

Common RGBW chip types you\’ll encounter include the 5050 SMD package and popular addressable LEDs like the SK6812 and WS2812B variants. These come in both addressable versions—enabling pixel-level control for dynamic lighting effects—and non-addressable options suited for simpler setups.

Choosing addressable RGBW LEDs offers benefits like precise digital control and custom animations, whereas non-addressable types are often more cost-effective for static lighting needs. Whether you need flexible strips or rigid RGBW LED PCB modules, understanding these core differences helps tailor your choice to the project.

For more insight on the quality benefits and uses of these LEDs, check out our detailed overview of the high CRI RGBW lighting advantages.

RGBW vs. RGB: A Detailed Comparison

When choosing between RGBW LED and traditional RGB, it boils down to how each handles color and white light, as well as factors like brightness, efficiency, and heat management. Here’s a quick comparison to help you decide which suits your project best.

| Feature | RGB LED | RGBW LED |

|---|---|---|

| White Light Quality | Created by mixing RGB channels; often off-white or tinted | Dedicated white channel delivers pure, crisp white light with high CRI (>90) |

| Color Rendering (CRI) | Typically 70-80, less natural colors | 90+ CRI, better color accuracy and saturation |

| Brightness | Lower when white needed; limits overall luminosity | Brighter whites and richer colors without sacrificing intensity |

| Energy Efficiency | Less efficient for white light, requires all 3 channels | More efficient due to dedicated white LED, saves power |

| Heat Management | Lower power, but more heat if running full white via RGB mix | Slightly higher thermal demand but better managed on well-designed RGBW PCBs |

| Applications | Budget lighting, simple effects, basic color changing | Architectural lighting, stage shows, high-end smart homes, commercial interiors |

| Cost Considerations | Less expensive upfront and simpler to control | Higher initial cost but better performance and versatility |

When to Choose RGBW

- You need high-quality white light with excellent color rendering.

- Your project demands vivid colors and smooth blending.

- Energy efficiency and long-term heat management matter.

- You are designing advanced lighting fixtures like smart home systems or architectural displays.

When RGB is Enough

- Budget constraints are tight.

- White light accuracy is not critical.

- Simpler setups with basic color effects suffice.

For complex RGBW designs, the right PCB is key to managing heat and ensuring consistent performance. Our experience as an RGBW assembly manufacturer means we can help you optimize your design, whether that’s a flexible strip or a rigid LED board.

For more on white LED design, check our detailed guide on the white LED light circuit PCB board.

PCB Design Considerations for RGBW LEDs

Designing a reliable RGBW LED PCB means carefully choosing the right substrate and layout to get the best performance and longevity. For thermal performance, Aluminum MCPCBs are the preferred choice as they efficiently dissipate heat, crucial for high-power RGBW LEDs. On the other hand, if flexibility is a priority—like for curved or wearable lighting—FR4 boards or flexible PCBs (FPCBs) offer the needed bendability without sacrificing too much durability.

When laying out your PCB, pay close attention to:

- Trace width: Use wider traces for power lines to reduce voltage drop.

- Thermal vias: Integrate multiple vias connecting the LED pads to the metal core to draw heat away and prevent hotspots.

- Component placement: Keep the high-heat LEDs spaced and arrange components to balance heat distribution.

Proper power distribution is key, especially with RGBW’s four channels, which means integrating compatible drivers that handle current loads efficiently and support dimming or color control smoothly.

Heat management doesn’t stop at substrate choice—high-density RGBW PCB designs need extra attention with heat sinks or thicker copper layers. This reduces thermal stress and prolongs LED life.

Aesthetics also impact design. A black PCB finish often enhances contrast and minimizes light bleed for cleaner visuals in RGBW strips, while a white PCB helps reflect light, boosting overall brightness—ideal for fixture designs where light output is a priority.

For a detailed dive into substrate options and layout best practices, check out our guide on design considerations for LED circuit boards. If thermal management is your main concern, exploring our custom high-power aluminum LED PCB solutions is a good place to start.

Types of RGBW LED PCBs and Fixtures

RGBW LED PCBs come in several forms to fit different lighting needs and design challenges:

- Flexible RGBW LED strips (FPCB): These are perfect for curved or irregular surfaces. Their bendable nature makes them ideal for signage, wearable tech, or architectural accents where space and shape are limited.

- Rigid RGBW LED boards: Used in more stable setups like modules and panels, these PCBs provide strong mechanical support, making them a go-to choice for commercial lighting and display fixtures.

- RGBW COB (Chip-on-Board) LED modules: COB technology places many RGBW LED chips directly on the PCB substrate, creating bright, seamless illumination with minimal hotspots. This is excellent for high-density lighting in applications such as stage lighting and architectural facades.

- Addressable RGBW pixel boards: These PCBs allow individual control of each RGBW LED, enabling dynamic lighting effects and color animations critical for smart lighting systems and entertainment setups.

- Custom-shaped RGBW LED PCBs: Beyond standard strips and panels, custom shapes like circular rings, linear bars, or matrix arrays are becoming popular. These tailored designs cater to specialized product requirements, enhancing both aesthetics and function.

Choosing the right type depends on your project’s shape, flexibility, brightness needs, and control complexity. Our expertise in custom RGBW PCB design ensures you get a tailored solution that perfectly matches your lighting goals.

Manufacturing and Assembly Process of RGBW LED PCBs

Manufacturing RGBW LED PCBs starts with precise schematic design, ensuring every LED channel—Red, Green, Blue, and White—is correctly mapped for optimal performance. After design finalization, the PCB moves to SMT (Surface Mount Technology) assembly, where RGBW LED chips and other components are carefully placed and soldered using automated machines for accuracy and consistency.

Quality control is crucial at multiple stages. We perform bin sorting to ensure all RGBW LEDs have uniform color output and brightness. Aging tests simulate real-world usage to catch potential failures early. Additionally, CRI (Color Rendering Index) verification confirms the white channel delivers natural and vibrant lighting with a high CRI, often above 90, essential for premium lighting applications.

Prototyping turnaround is swift, letting customers test their custom RGBW LED PCB designs rapidly. As production scales, we maintain strict standards to address common challenges like solder joint reliability—which, if ignored, can cause intermittent failures—and EMC (Electromagnetic Compatibility) protections, essential for minimizing interference in complex RGBW LED systems.

For detailed assembly capabilities and custom LED control PCB board solutions, consider our LED PCB assembly services and LED control PCB board assembly companies pages, where we offer expert support from prototype to large-scale runs.

Applications of Custom RGBW LED PCBs

Custom RGBW LED PCBs are incredibly versatile and fit perfectly across various industries, thanks to their ability to deliver vibrant colors and pure white light with high CRI. Here are some key applications where our custom RGBW LED assemblies really shine:

- Architectural and Facade Lighting: RGBW LEDs add dynamic color accents and crisp white illumination to building exteriors. Their superior color rendering makes features stand out while providing energy-efficient ambient light.

- Stage and Entertainment Fixtures: From concerts to theaters, RGBW LED PCBs enable rich, immersive lighting effects with smooth color transitions and bright whites for natural highlights, elevating any performance environment.

- Smart Home and Commercial Interiors: Custom RGBW LED strips and modules create mood lighting, functional task lighting, and decorative accents that adapt easily to smart controls, adding elegance and convenience to modern spaces.

- Automotive and Display Signage: Reliable and compact, RGBW LED PCBs deliver bright, high-quality light for vehicle lighting systems and eye-catching signs, ensuring visibility and color accuracy.

Many clients have benefited from tailored solutions incorporating flexible RGBW FPCBs or high-density rigid boards, customized to their specific needs with optimized thermal management and driver integration. For instance, a recent architectural project used our specialized RGBW fixtures to achieve both vivid illumination and uniform white light for a landmark building facade.

To explore more about custom LED solutions that suit your unique project, check out our detailed overview of custom LED board design and the advantages of aluminum LED PCBs to improve thermal performance and reliability.

Choosing a Reliable RGBW LED PCB Manufacturer

Picking the right manufacturer for your custom RGBW LED and PCB needs is crucial for performance and long-term success. Focus on these key factors when choosing a partner:

- Experience with LED-specific PCBs: Look for suppliers familiar with the unique thermal and electrical demands of RGBW LED PCBs. Experienced manufacturers understand how to optimize layouts for heat dissipation and color consistency.

- Rapid prototyping capabilities: Speed matters. A manufacturer that offers fast prototyping helps you test and refine your design quickly before scaling up production.

- Certifications: UL and RoHS certifications ensure your RGBW LED PCB meets safety and environmental standards, essential for global markets.

- Custom design expertise: Since RGBW systems vary widely, a manufacturer skilled in custom RGBW PCB design can tailor solutions—from flexible RGBW FPCBs to rigid boards—matching your exact specs.

- Low MOQ and global supply: Reliable suppliers accommodate small batch orders without sacrificing quality and can scale up production worldwide as your needs grow.

Partnering with a specialized RGBW LED PCB manufacturer ensures you get high-CRI, energy-efficient lighting solutions with consistent color performance and robust durability. For detailed insights into our custom RGBW PCB design services or the LED manufacturing process, check out our custom RGB PCB assembly solutions and how LED PCBs are manufactured.

FAQs on RGBW LED PCBs

Are RGBW LED PCBs compatible with standard RGB controllers?

Most RGBW LED strips and PCBs require controllers specifically designed for four channels (Red, Green, Blue, White). Using a regular RGB controller won’t fully take advantage of the white channel. For optimal performance, use dedicated RGBW LED controllers or dimmers, such as those available in our LED light controller range.

Can I use addressable RGBW LEDs with custom PCB designs?

Yes, addressable RGBW LEDs like SK6812 or WS2812B variants integrate well with custom RGBW PCB designs. They allow pixel-level color control and dynamic lighting effects, ideal for smart lighting or stage setups. Make sure your PCB layout supports proper data lines and power distribution for these digital LEDs.

Are RGBW LED PCBs waterproof?

Waterproofing depends on the PCB’s construction and coating. Flexible RGBW FPCBs and rigid boards can be coated with silicone or epoxy for moisture resistance, making them suitable for outdoor or humid environments. It’s important to specify waterproof requirements during the design and manufacturing phase.

What should I keep in mind for RGBW LED PCB installation?

- Proper heat dissipation is crucial; consider aluminum MCPCBs for higher power setups.

- Use compatible controllers and power supplies rated for all four channels.

- Check wiring polarity and connections closely, especially for addressable RGBW LEDs.

- For flexible strips, avoid sharp bends to prevent damage.

- If mounting outdoors or in damp areas, ensure proper waterproofing and sealing.

If you need expert advice on custom RGBW PCB assembly or controller compatibility, our team is ready to assist. You can also explore reliable options like our PWM LED dimmer controller switch designed for smooth RGBW lighting control.