What is an LED Control PCB Board?

An LED control PCB board is a specialized printed circuit board designed to manage and regulate LED lighting systems. Its core functions include power distribution, dimming control, RGB color management, and seamless driver integration. These boards ensure efficient energy use while maintaining optimal brightness and color accuracy, making them essential in modern LED lighting solutions.

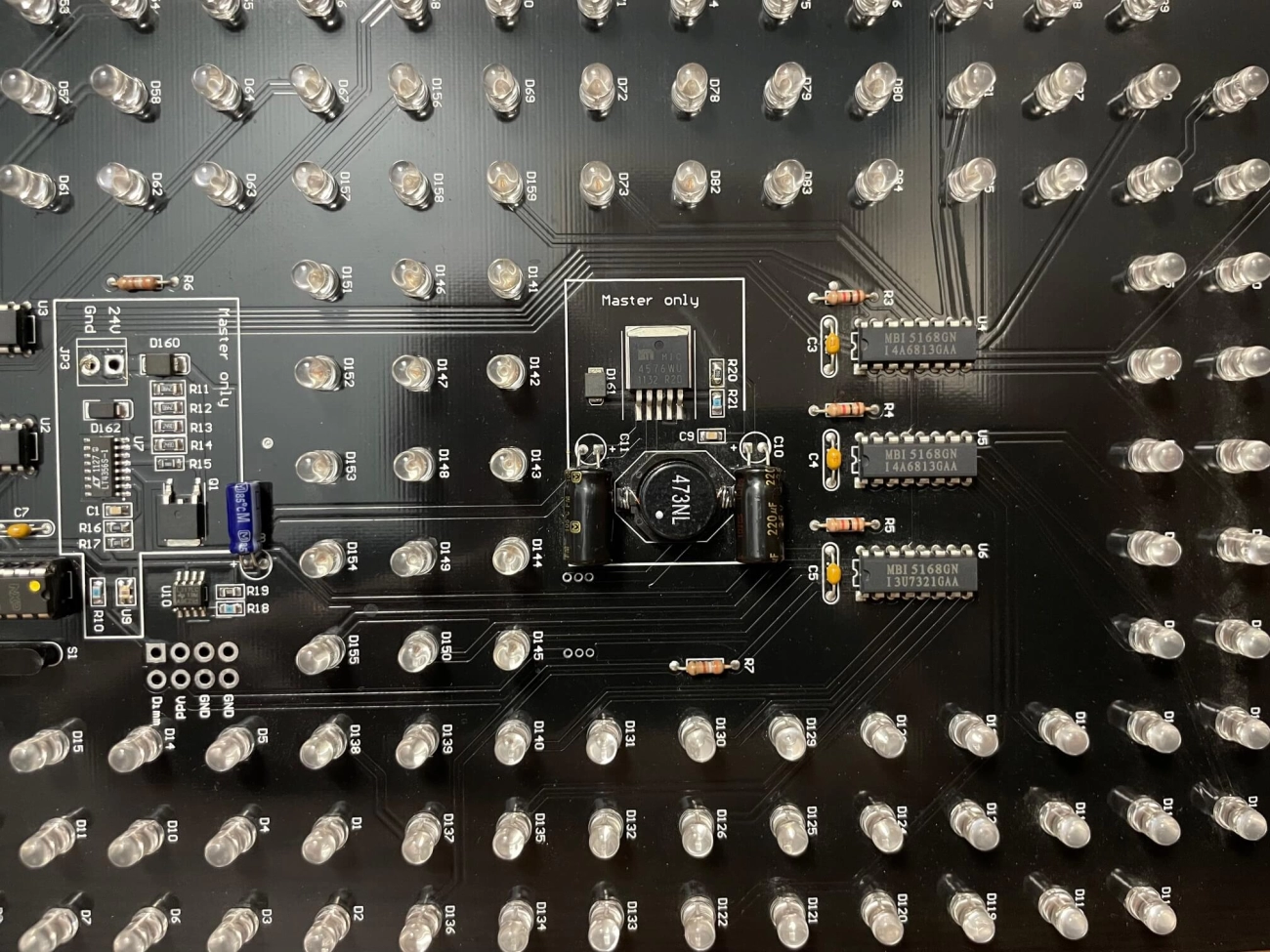

Unlike standard PCBs, LED control boards require enhanced thermal conductivity to dissipate heat effectively. This is crucial because LEDs and drivers generate significant heat during operation, which can impact performance and lifespan if not properly managed.

There are several common types of LED PCB and LED control PCB boards to suit different applications:

- Single-layer PCBs: Simple and cost-effective, ideal for low-complexity LED setups.

- Multi-layer PCBs: Provide higher density and better signal integrity for complex circuits.

- Aluminum-core PCBs: Offer superior heat dissipation, perfect for high-power LED applications.

- Flexible PCBs: Adaptable and lightweight for curved or compact designs.

- Rigid-flex PCBs: Combine the strength of rigid boards with the flexibility of flexible circuits for robust, space-saving solutions.

Choosing the right type of board depends on your project’s power requirements, heat management needs, and physical constraints. Understanding these differences is key when searching for reliable LED control board PCB assembly companies or sourcing custom solutions.

Why Custom LED Control Boards Matter

Custom LED control boards offer clear benefits over off-the-shelf options. By tailoring layouts to your specific needs, these boards optimize heat dissipation and improve overall longevity. This means better performance in demanding environments and longer-lasting LEDs.

Benefits of Custom LED Control Boards

- Tailored design: Custom layouts fit unique applications perfectly

- Optimized thermal management: Reduces overheating and extends lifespan

- Enhanced reliability: Fewer compatibility issues with drivers and components

- Scalability: Easily adapt for small or large production runs

Challenges with Off-the-Shelf Boards

| Issue | Impact |

|---|---|

| Poor thermal management | Leads to overheating and failures |

| Limited scalability | Not flexible for different volumes |

| Compatibility issues | Driver and LED mismatches |

Custom boards avoid these pitfalls, ensuring your LED control system works efficiently from day one.

Real-World Applications

Custom LED control boards are essential in:

- Street lighting

- Automotive headlights and tail lights

- Agricultural grow lights

- Medical and surgical illumination

- IoT-enabled smart lighting systems

For projects like automotive lighting, seeing how custom tail light LED boards enhance performance is a prime example of tailored solutions in action. Similarly, custom boards used in smart LED lighting align well with modern IoT control requirements, offering flexible and reliable designs.

Choosing custom LED control boards helps you meet exact specifications while overcoming the limits of generic products, making them the smart choice for advanced LED control needs.

The LED Control PCB Assembly Process

Assembling an LED control PCB board involves several clear steps to ensure quality and performance.

Step 1: Design and DFM Review

The process starts with detailed design and Design for Manufacturability (DFM) reviews. This ensures the PCB layout meets thermal management and electrical requirements for LED driver PCB assembly, minimizing production issues.

Step 2: Material Selection

Choosing the right materials is critical. Common options include aluminum substrates for excellent heat dissipation, FR-4 for standard circuits, and copper cladding to enhance conductivity. These choices impact the durability and efficiency of your LED control board.

Step 3: PCB Fabrication

Next is the actual PCB fabrication, where layers are built up according to the design specs. This includes single-layer, multi-layer, or specialized types like aluminum-core or flexible LED control PCBs. You can explore detailed fabrication options like custom high-power aluminum LED PCB manufacturing for advanced thermal needs.

Step 4: Component Sourcing and SMT/Through-Hole Assembly

Sourcing quality LEDs, drivers, and control components is essential. The assembly typically uses Surface Mount Technology (SMT) for compact, high-density boards or DIP through-hole methods for robust connections, especially in high-power applications.

Step 5: Reflow Soldering, Testing, and Quality Assurance

Once assembled, boards undergo reflow soldering to secure components. Automated Optical Inspection (AOI), functional tests, and thermal evaluations verify that each LED control circuit board performs as expected, ensuring reliability in real-world use.

Turnkey vs. Consignment Options

Many LED control pcb board assembly companies offer turnkey services, handling everything from design to delivery. Alternatively, consignment assembly allows you to supply components for assembly only, providing flexibility based on your production needs.

This structured assembly process guarantees your custom LED control boards deliver optimal performance and longevity. For more on flexible PCB solutions, check out our LED flexible PCB with LEDs options.

Key Factors in Choosing LED Control PCB Assembly Companies

When selecting LED control PCB board assembly companies, experience with LED-specific challenges is crucial. Look for partners skilled in thermal management LED PCB design since heat dissipation directly impacts the lifespan and performance of your LED boards. Their expertise should cover high-density component placement and advanced techniques like COB (Chip On Board) and mixed assembly to ensure reliability and efficiency.

Capabilities matter too. Whether you need LED controller board prototyping, low-volume production, or high-volume scaling, your assembly company should flexibly handle your project size without compromising quality. Clear communication on lead times and pricing transparency helps avoid surprises during production.

Certifications are another must-check. Trusted manufacturers typically hold ISO 9001, RoHS compliant LED PCBA, UL, and for automotive-grade products, IATF certification. These show a commitment to quality and regulatory standards, essential for global market compatibility.

Finally, excellent customer support rounds out the ideal choice. Your supplier should guide you through design consultations, SMT assembly for LED controls, and thorough testing to ensure your custom LED control boards meet exact requirements. Companies with deep thermal management knowledge and turnkey service options stand out as reliable partners in LED control PCB manufacturing.

Top Considerations for Custom LED Control Board Projects

When planning custom LED control boards, several key factors can make or break your project’s success:

Thermal Design Optimization

Efficient thermal management is critical for both brightness and lifespan. Good heat dissipation prevents premature LED failure and maintains consistent performance. This often means choosing the right substrates like aluminum or advanced designs that handle heat effectively.

Component Quality

Using premium LEDs from trusted brands like Cree, Osram, or Nichia ensures higher reliability and better light output. Likewise, quality LED drivers and control chips safeguard stable operation, especially in demanding applications.

Prototyping for Small Batches

Rapid prototyping allows you to test designs, verify thermal behavior, and tweak functionality before scaling. Small-batch runs reduce risk and speed up your development cycle.

Cost-saving Without Sacrificing Quality

Smart sourcing and optimized layouts can cut costs. Work with LED control PCB assembly companies that offer efficient SMT assembly for LED controls to balance expenses and quality.

Sustainability Matters

Eco-friendly manufacturing using recyclable materials and processes is increasingly important. Going green not only benefits the environment but can also improve your brand’s appeal.

For more on design strategies that improve LED circuit performance, check out our detailed guide on design considerations for LED circuit boards.

Why Choose Custom LED Control Boards?

Choosing custom LED control boards means you get specialized manufacturing tailored to your exact needs—no generic solutions here. Whether it\’s a unique layout, specific driver integration, or advanced thermal management, custom boards ensure your project performs exactly as intended.

Full-Service Support

From initial design consultation to SMT assembly and testing, custom LED control board suppliers provide end-to-end services, handling everything under one roof. This means faster turnaround and consistent quality throughout production.

Proven Track Record

Many custom LED control board manufacturers excel in small-batch and custom production runs, perfect for specialized applications or prototype phases. This experience guarantees your custom LED driver PCB assembly matches industry standards while meeting your timeline.

Key Benefits at a Glance

| Advantage | Description |

|---|---|

| Tailored Solutions | Designed for your specific application needs |

| Quality Assurance | Strict testing ensures reliable performance |

| Quick Turnaround | Fast prototyping and production timelines |

| Competitive Pricing | Cost-efficient for small and large volumes |

| Technical Expertise | Advanced knowledge of thermal and electrical design |

Custom LED control boards give you unbeatable control over your product’s performance, longevity, and scalability—qualities often missing in off-the-shelf options. When precision and quality matter, custom is the way to go.