Understanding Quantum PCB Boards for LED Horticulture Lighting

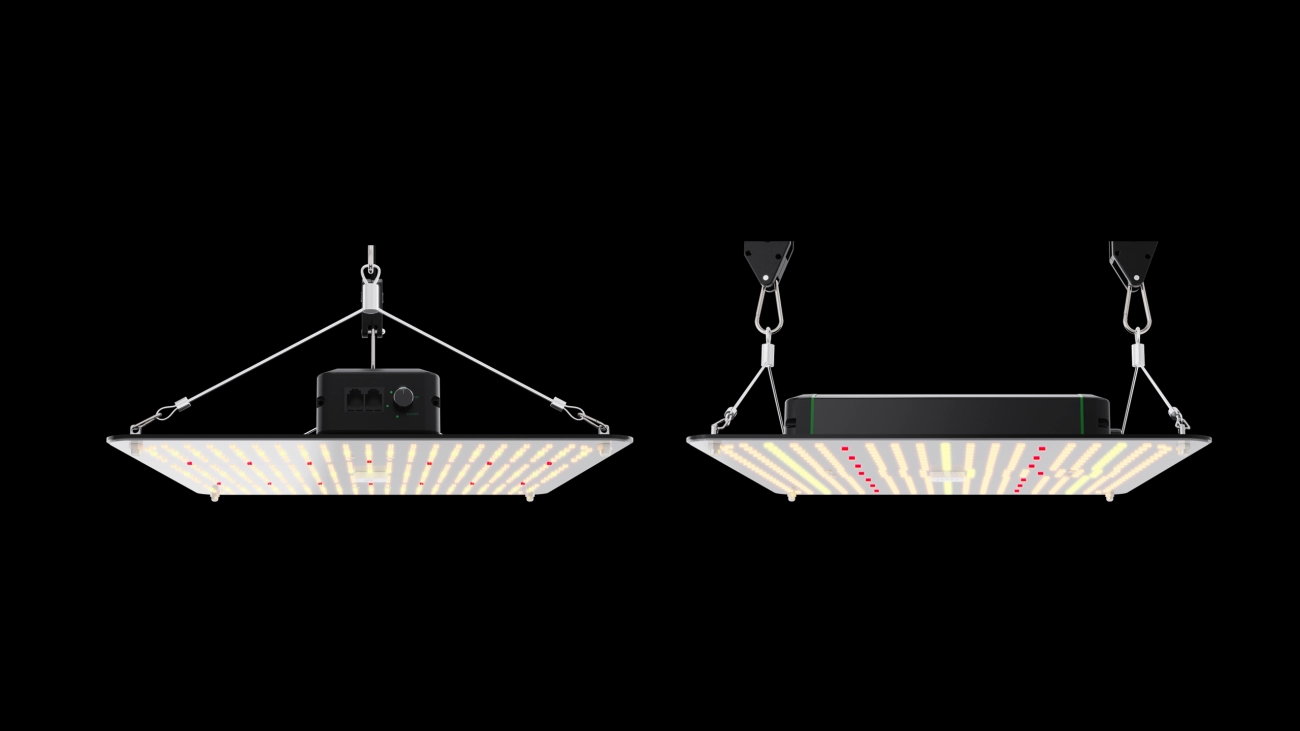

Quantum PCB boards are specialized aluminum-based printed circuit boards designed specifically for horticulture LED lighting. Unlike traditional LED setups, these boards feature hundreds of mid-power SMD LEDs—such as those from the Samsung LM301 series—arranged evenly across a flat surface. This layout ensures consistent light distribution, making them ideal for indoor plant growth.

The rise of quantum boards in the horticulture sector is tied to their ability to offer uniform PPFD (photosynthetic photon flux density) across the canopy without hotspots—a common issue with older designs like COB (chip-on-board) LEDs or linear LED strips. Indoor growers increasingly prefer quantum LED boards because they combine high efficiency, excellent heat dissipation, and adaptable sizing, meeting the diverse needs of both home growers and commercial operations.

Key distinctions that set quantum PCB boards apart include:

- Metal Core PCB (MCPCB) design: Uses aluminum substrates for superior thermal management.

- Dense LED arrays: Hundreds of mid-power SMD LEDs rather than fewer, high-power chips.

- Uniform light spread: Reduced shadowing and better canopy penetration.

- Modular sizing: Easier to scale from small 100W boards to industrial 800W+ configurations.

Overall, LED quantum PCB boards offer a modern, efficient, and versatile solution for horticulture lighting applications where even light and energy efficiency are top priorities.

How Quantum PCB Boards Work

Quantum PCB boards start with a sturdy metal core, usually aluminum, which plays a crucial role in soaking up and releasing heat efficiently. This metal core PCB grow design prevents overheating, boosting the lifespan and performance of the LEDs. On top of the aluminum base, multiple copper layers handle electrical connections with precision, while a solder mask protects the circuitry from dust and moisture, ensuring reliability in various grow environments.

The heart of these boards lies in their LED chip integration. Most LED quantum PCB boards use highly efficient diodes such as the Samsung LM301 series, known for great light output and energy savings. These LEDs are wired in clever series-parallel strings to balance voltage and current, providing stable operation even across large boards.

For lighting performance, quantum boards focus on distributing light evenly over the canopy. The arrangement of hundreds of mid-power SMD LEDs ensures a uniform PPFD level, which means plants get consistent light intensity with minimal hotspots. This uniformity enhances canopy penetration and supports healthy, even growth across your entire indoor grow space.

If you want to learn more about quality PCB design options for LEDs, explore our LED strip PCB board and LED light driver PCB board assemblies ideal for tailored horticulture lighting systems.

Key Benefits of Using Quantum PCB Boards in Grow Lights

Quantum PCB boards for LED grow lights offer a range of advantages that make them a top choice for indoor horticulture. Here’s why they stand out:

Uniform Light Distribution

Quantum boards feature an array of mid-power SMD LEDs spaced evenly, ensuring consistent light with no hotspots. This improves canopy penetration, letting plants receive uniform photosynthetic photon flux density (PPFD) for better growth.

High Energy Efficiency

These boards can deliver efficiencies between 2.8 to 3.0 µmol/J, maximizing output for the energy consumed. This means stronger light with less electricity compared to traditional LED designs.

Lower Operating Temperatures

Built on metal-core PCB substrates, quantum boards dissipate heat efficiently. This reduces the need for active cooling, prolonging LED life and cutting down noise and maintenance costs.

Cost-Effective Scalability

Quantum PCB boards are easy to scale from small-scale home setups to large commercial farms. Their modular design enables flexible wattage configurations, reducing upfront costs without sacrificing output.

Passive Cooling Benefits

Efficient thermal management through the aluminum MCPCB means many quantum boards run cool enough to rely mainly on passive cooling. This eliminates or reduces the need for fans, lowering power use and increasing system reliability.

| Benefit | Description | Impact |

|---|---|---|

| Uniform Canopy Coverage | Evenly spaced LEDs for consistent light | Improved plant growth and yield |

| High Efficiency | Up to 3.0 µmol/J light output per watt | Lower electricity costs |

| Effective Heat Dissipation | Metal core PCB substrate enhances cooling | Longer LED lifespan, quieter operation |

| Scalable Design | Adaptable wattage from 100W to 800W+ | Fits various grow room sizes |

| Passive Cooling | Reduced active fan usage | Energy savings and less noise |

If you want detailed options on high-quality LED circuit boards, check out our range of 2835 LED light PCB boards for reliable performance in horticulture lighting.

In short, quantum LED PCB boards combine efficiency, durability, and adaptability, making them perfect for growers aiming to improve their lighting system’s performance and energy profile.

Technical Specs to Watch for in LED Quantum PCB Boards

When choosing a led quantum pcb board, keeping key specs in mind ensures you get the best performance and reliability. Here’s a quick breakdown:

| Specification | What to Look For | Notes |

|---|---|---|

| Board Size | From 100mm x 100mm up to custom large formats | Matches your grow space and fixture |

| Wattage Range | Typically 100W to 800W+ | Higher wattage for bigger grows |

| LED Count & Type | Hundreds of mid-power SMD LEDs (e.g., Samsung LM301 series) | More diodes = better coverage and intensity |

| Light Spectrum | Full spectrum white light + options like deep red, UV, IR | Tailor to plant growth stages and species |

| Thermal Management | Aluminum MCPCB with proper substrate thickness (1.0-2.0mm), copper weight (≥2oz), and heatsink compatibility | Critical for lasting performance and heat dissipation |

| Driver Needs | Constant current drivers preferred; support for dimming (PWM or analog) | Ensures LED longevity and flexible light control |

Why Thermal Features Matter

Using a metal core PCB (MCPCB) substrate with adequate thickness and copper layers helps spread heat swiftly. This passive cooling reduces spots of overheating, prolonging LED life and keeping output stable. Pairing this with a compatible heatsink further lowers operating temperature.

Spectrum Flexibility

Most growers prefer full spectrum PCBs for balanced growth, but boosts in deep red or adding UV/IR diodes can improve flowering or plant resilience. Customizing the spectrum on your quantum board means better results tailored to crops.

For connection with dimming, learn more about PWM LED dimming versus constant current dimming for precise control in grow light setups.

Keeping these details front and center helps when planning or customizing your plant light quantum module—whether for a small home setup or a large commercial farm.

Customization Options for Quantum PCB Boards

When it comes to custom LED quantum PCB boards, flexibility is key. Manufacturers offer various options to tailor boards to your exact horticulture lighting needs:

- Board Dimensions & Shapes: Choose from standard rectangular shapes or opt for round and irregular forms to fit unique fixture designs.

- LED Density: Adjust the number of SMD LEDs to balance light intensity and power consumption.

- Spectrum Tuning: Customize light spectrum based on plant growth stages—vegetative, flowering, or specific crops. This includes adding deep red, UV, or IR LEDs to standard full-spectrum boards.

- Premium Components: Integrate top-bin LED chips like Samsung LM301B or LM301H for higher efficiency and longevity.

- Additional Features: Options such as waterproof coatings, enhanced thermal substrates, or reinforced copper layers improve durability and performance.

| Customization Aspect | Options Available | Benefits |

|---|---|---|

| Board Shape | Rectangular, round, irregular | Fit various fixture types |

| LED Density | Low to high LED counts | Control brightness and power usage |

| Spectrum | Full spectrum, deep red, UV, IR boosts | Optimize plant growth and yield |

| Components | Samsung LM301B, other premium diodes | Boost efficiency and lifespan |

| Protective Features | Waterproofing, thicker substrates | Durable, stable operation |

Choosing a custom grow light board from experienced suppliers ensures you get reliable build quality and optimized performance. Customization not only adapts your setup for better plant growth but also reduces wasted energy and heat.

If you want to explore tailored solutions that work perfectly for your indoor grow setup, check out our range of custom aluminum PCB LED lighting boards designed for high-efficiency horticulture.

This focused customization helps growers worldwide fine-tune their lighting setups, making LED quantum PCB boards a smart, scalable investment.

Manufacturing and Quality Standards

When it comes to led quantum PCB boards, the choice of materials is crucial. We prioritize high-quality aluminum substrates that offer excellent heat dissipation and durability, ensuring stable performance over time. Using top-bin LED chips, such as the Samsung LM301 series, guarantees consistent light output and efficiency.

Our manufacturing process relies on advanced SMT assembly techniques, allowing precise placement of hundreds of mid-power SMD LEDs to create a uniform diode array board. Every board undergoes thorough testing for light efficacy, color accuracy, and electrical reliability before shipment.

We also adhere to strict quality certifications and industry standards, which help maintain long-term performance. Most of our custom quantum LED PCBs are designed to last over 50,000 hours, reflecting their robust build and reliable materials.

For those interested in premium production processes and durable designs, our expertise in aluminum MCPCB and grow light PCB assembly offers a trustworthy solution. Check out our page on custom high-power aluminum LED PCB for more insights into our manufacturing excellence.

Applications in Indoor Growing

LED quantum PCB boards have become a reliable choice across a variety of indoor growing setups. Whether you’re managing a small-scale home grow, a commercial horticulture facility, or large-scale vertical farming, these boards offer adaptable solutions that deliver consistent results.

Ideal Environments for Quantum PCB Boards

- Home grows: Compact and efficient, they provide uniform light without overheating small spaces.

- Commercial facilities: Scalable designs from 100W to 800W+ power options fit different room sizes and crop densities.

- Vertical farms: Customizable shapes and high-density LED arrays ensure even canopy coverage on multiple layers.

Lighting Performance Across Growth Stages

Quantum LED PCB boards deliver uniform PPFD across the entire canopy, which is key to healthy vegetative growth and robust flowering development. Because the light spreads evenly, plants receive consistent exposure that supports photosynthesis and promotes stronger yields.

Real-World Benefits

- Yield improvements: Growers often report increased biomass and flower production thanks to the optimized spectrum and light uniformity.

- Energy savings: High-efficiency boards using top-tier diodes like the Samsung LM301 series provide up to 3.0 µmol/J, reducing power consumption without sacrificing output.

- Lower heat output: Passive cooling in the metal core PCB design helps keep operating temperatures down, which minimizes stress on plants and lowers cooling costs.

For growers looking for reliable, energy-efficient LED lighting, integrating a custom grow light PCB board can be a game-changer. Check out our range of LED light driver boards and premium SMD LEDs to build an end-to-end lighting system optimized for indoor horticulture.

Sourcing and Assembly Considerations for LED Quantum PCB Boards

When looking to source a custom LED quantum PCB board, choosing a reliable China-based manufacturer is crucial. China offers a wide range of suppliers specializing in LED quantum PCB board assembly services with experience in handling different sizes, diode counts, and spectrum requirements. Working with trusted factories ensures you get high-quality aluminum MCPCB boards with consistent performance and reliability.

Several factors affect the overall cost when ordering quantum boards from China:

- Order volume: Larger batches usually lower the per-unit price.

- Component selection: Using premium diodes like Samsung LM301 series can increase costs but improve efficiency and lifespan.

- Assembly complexity: Custom wiring layouts or additional features like waterproofing add to labor and testing expenses.

To smoothly integrate your quantum board into a full grow light fixture, consider these tips:

- Coordinate with your supplier on driver compatibility, ensuring the board suits constant current or dimmable driver requirements.

- Confirm mechanical dimensions match your fixture frame or heat sink to optimize thermal management.

- Plan reflector or lens installation based on your uniform light distribution needs.

By partnering with an experienced manufacturer offering turnkey grow light PCB assembly solutions, you streamline production and reduce delays. For more advanced options and assembly capabilities, explore professional SMT services and LED control PCB assembly companies that specialize in horticulture lighting setups.

Learn more about reliable LED PCB assembly services and SMT assembly in China to make informed sourcing decisions that boost your grow operation efficiency.

Elevate Your Grow with Tailored LED Quantum PCB Boards

In today’s horticulture scene, choosing the right LED quantum PCB board can make a real difference. Custom LED quantum PCB boards offer unmatched benefits—uniform light distribution, high energy efficiency, and reliable thermal management—which translate into healthier plants and better yields. Their flexibility in design, spectrum tuning, and scalable power options means growers can tailor lighting precisely to their crop’s needs, minimizing waste and maximizing growth efficiency.

Working with experienced manufacturers ensures you get premium materials, advanced assembly, and performance tested solutions that last 50,000+ hours. Whether you run a small home grow or large commercial vertical farm, custom quantum boards provide a cost-effective, passive cooled, and high-performance alternative to standard grow light setups.

For growers ready to boost their results, exploring custom solutions is key. Consider specialized custom grow light boards and options featuring top-tier components like Samsung LM301 diodes to match your exact horticulture goals. This level of customization allows you to upgrade your setup with high-efficiency quantum LED technology built right into your PCB.

If you want to ensure maximum PPFD uniformity, long-term reliability, and tailored spectrum support, custom LED quantum PCB boards from trusted suppliers in China can deliver precise, scalable solutions. Investing in these advanced boards means elevating your indoor garden with technology designed to keep plants thriving and energy costs down.

Explore your options for a custom LED quantum PCB board today and unlock the next level of horticultural lighting performance.