If you’re working with LED lighting, you’ve probably heard about the 2835 LED light PCB board – a game-changer in efficiency and design flexibility. These compact 2835 SMD LEDs pack impressive brightness and reliability into a small footprint, making them a top choice for everything from residential strips to industrial panels. But not all PCB boards are created equal. Whether you’re a lighting designer, manufacturer, or DIY enthusiast, understanding how to choose or customize the perfect PCB board for your 2835 LEDs can elevate your project’s performance and lifespan. Let’s explore why the right 2835 LED PCB board is essential for creating efficient, durable, and tailored lighting solutions.

Understanding the 2835 SMD LED Chip

The 2835 SMD LED is a popular surface-mount device widely used in LED lighting due to its efficiency and compact size. Here’s a quick look at its technical specifications:

| Specification | Details |

|---|---|

| Size | 2.8mm x 3.5mm |

| Power Rating | 0.2W to 0.5W per LED |

| Luminous Efficacy | Up to 120+ lumens per watt |

Compared to other common SMD LEDs:

| LED Type | Size (mm) | Power (W) | Brightness (Lumens) | Notes |

|---|---|---|---|---|

| 2835 | 2.8×3.5 | 0.2-0.5 | High | High luminous efficiency |

| 3528 | 3.5×2.8 | 0.08-0.1 | Moderate | Lower brightness, cheaper |

| 5050 | 5.0×5.0 | 0.2-0.24 | Very bright | Can house 3 chips, RGB options |

| 3014 | 3.0×1.4 | 0.1-0.2 | Moderate | Slim profile, space-saving |

How Wavelength Determines LED Color

The color produced by an LED depends on its wavelength—the distance between light wave peaks measured in nanometers (nm). Different wavelengths correspond to different colors:

- Visible spectrum range: ~380 nm (violet) to 750 nm (red)

- For white LEDs like the 2835, phosphor coatings convert blue or UV wavelengths to broader white light.

- Colored LEDs emit specific wavelengths: red (~620–630 nm), green (~520–530 nm), blue (~450–460 nm).

By choosing the right wavelength and phosphor mix, manufacturers tailor LEDs for various applications ranging from warm white ambiance to vibrant, colored lighting.

Understanding these basics helps explain why 2835 LED light PCB boards are so versatile and favored in modern lighting design, balancing size, brightness, and color quality.

Common Color Temperatures for 2835 White LEDs

2835 LED light PCB boards commonly use several key color temperatures, each suited for specific environments:

- Warm White (2700K–3000K): Perfect for residential spaces and hospitality settings, warm white offers a cozy, inviting glow. It’s ideal for living rooms, hotels, and restaurants where comfort matters most.

- Neutral White (4000K–4500K): This balanced tone works well in offices and retail stores, providing clear, natural lighting that enhances productivity and displays without being too harsh.

- Cool White (5000K–6500K): Often chosen for task lighting and commercial spaces, cool white provides bright, crisp illumination. It’s great for workshops, medical facilities, and areas needing high visibility.

Additionally, tunable and CCT-adjustable 2835 white LEDs offer flexibility by letting users switch between these temperatures to suit varying moods and tasks. For more on the practical uses and specs of these LEDs, check out our detailed guide on the white light SMD 2835 LED.

Using the right color temperature on your 2835 LED PCB board ensures better ambiance, energy efficiency, and visual comfort tailored to every application.

Applications of Different Colored 2835 LEDs

2835 LED lights come in various colors, each suited to specific uses. Here\’s a quick look at where different colored 2835 LEDs shine best:

| LED Color | Typical Applications |

|---|---|

| White LEDs | Panels, LED strips, downlights, ceiling lights, task lighting |

| RGB & Specialty Colors | Architectural lighting, signage displays, automotive lighting, horticulture grow lights |

| High-Power White | High-bay fixtures, floodlights, linear lighting, bulb retrofits |

White 2835 LEDs are popular for general lighting thanks to their bright, even output. They\’re ideal for LED strips and panel lights used in homes, offices, and commercial spaces.

RGB and specialty colored 2835 LEDs open up creative possibilities. They\’re perfect for dynamic architectural lighting, eye-catching signage, automotive tail lights, and horticulture setups that require specific light spectra.

High-lumen 2835 LEDs in white are also common in high-bay lighting and floodlights, delivering powerful illumination in warehouses, stadiums, and outdoor spaces. Their efficient design makes them great for bulb retrofits and linear fixtures where space and heat management are concerns.

For more on these versatile LEDs, check out our range of 2835 LEDs and their applications in high CRI white LEDs.

Types of PCB Boards for 2835 LEDs

Choosing the right PCB board for your 2835 LED setup is key to performance and longevity. Here are the common types used:

- Aluminum MCPCB (Metal Core PCB): Ideal for high-power 2835 LEDs, aluminum MCPCBs excel in heat dissipation. This helps keep the LEDs cool and extends their life, making them perfect for high-efficiency 2835 LED applications like high-bay lighting and floodlights.

- FR4 Rigid Boards: A cost-effective and widely used standard, FR4 PCBs work well for general-purpose 2835 LED lighting. While they don’t dissipate heat as well as aluminum, they’re great for low to medium power designs and budget-friendly projects.

- Flexible PCBs: When designs require curved, narrow, or irregular shapes—like wearable lighting or tight spaces—flexible 2835 LED strip PCBs are the go-to option. Their bendability doesn’t compromise LED performance and allows creative install options.

- Single-layer vs. Multi-layer Designs: Single-layer PCBs are straightforward and cost-effective, suitable for simple lighting circuits. Multi-layer PCBs, on the other hand, provide better electrical performance and heat management for complex or high-power 2835 LED modules.

For efficient thermal management and tailored LED circuit board design, considering these board types is essential. We recommend exploring our detailed guide on LED light circuit board design to find the best fit for your 2835 LED projects.

Key Design Considerations for 2835 LED PCB Boards

Designing a 2835 LED light PCB board requires careful attention to several key factors to ensure optimal performance and longevity.

- Thermal management and heat sinking: The 2835 LEDs generate heat during operation, so using materials like aluminum MCPCB helps dissipate heat effectively. Proper heat sinking prevents overheating, which can reduce LED lifespan and efficiency.

- LED density and spacing: Achieving uniform light distribution depends on the right balance of LED density and spacing on the PCB. Too close means hotspots; too far causes uneven brightness.

- Voltage options: Common voltage setups include 12V and 24V, but constant current designs are often preferred for stable brightness and to extend LED life. Choosing the right driving method is crucial to protect your LEDs from voltage fluctuations.

- CRI levels and beam angles: High CRI (Color Rendering Index) 2835 LEDs ensure better color accuracy, important for applications needing natural light appearance. Beam angle selection affects how light spreads—wide beams suit panels and strips, while narrow beams focus light for task lighting.

Optimizing these design points in your custom 2835 LED circuit board boosts efficiency and performance. For more on LED control, check out our LED driver circuit design guide to pick the best power management solutions.

Benefits of Custom 2835 LED Light PCB Boards

Choosing a custom 2835 LED light PCB board brings several clear advantages over generic options:

Tailored Sizes and Shapes

Design your PCB exactly how you need it — whether it’s round, square, or uniquely shaped. This flexibility lets you fit LEDs perfectly into your device or fixture.

Optimized Layouts

Custom layouts mean better LED placement and spacing, which improves light uniformity and reduces hotspots. It also supports your specific wiring and connection preferences.

Enhanced Efficiency and Longevity

A well-designed PCB improves thermal management, keeping LEDs cool. This leads to higher efficiency, less power waste, and longer-lasting lights.

Improved Performance

Custom boards can support specific voltage options (like 12V or 24V) and include features such as constant current control, improving overall LED stability and output.

Cost Savings via Optimized Manufacturing

Optimizing PCB design for your exact needs can lower material waste and assembly costs. As a result, you get better value with no compromises on quality.

| Benefit | What it Means for You |

|---|---|

| Tailored Sizes & Shapes | Perfect fit for your application |

| Optimized Layouts | Better light quality and wiring ease |

| Enhanced Efficiency | Lower energy use, longer lifespan |

| Improved Performance | Stable brightness and color output |

| Cost Savings | Smarter production, cheaper overall |

Customizing your 2835 LED PCB lets you control every detail to create an efficient, durable, and cost-effective lighting solution.

For those interested in custom LED solutions, exploring options like our custom LED circuit boards can help you find the right fit for your next project.

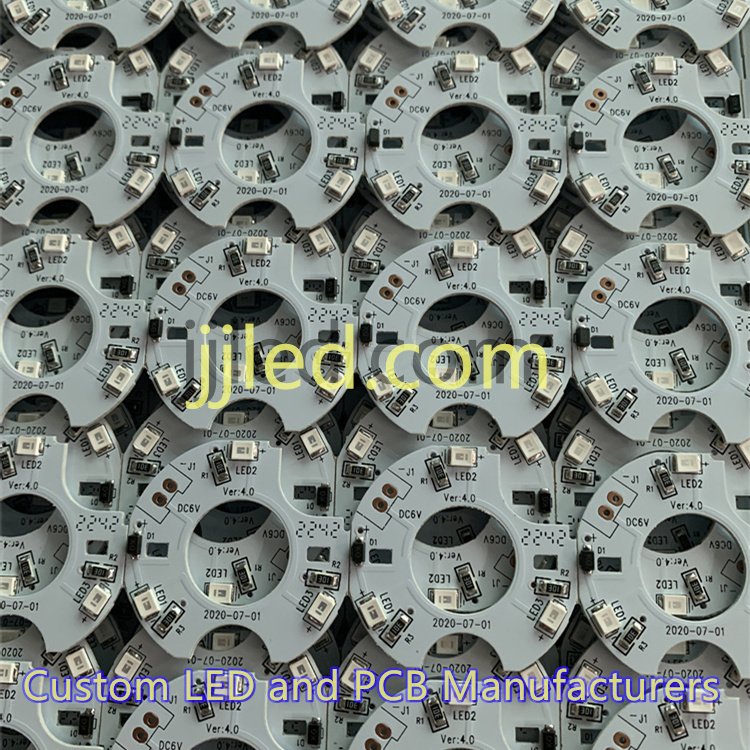

Why Choose Us as Your Custom 2835 LED Light PCB Board Manufacturer

Choosing the right partner for your custom 2835 LED light PCB board is essential for quality, reliability, and performance. Here’s why we stand out:

| Feature | Benefit |

|---|---|

| Expertise in Aluminum & Flexible Boards | Superior thermal management and versatile designs for all applications |

| Full Customization | From prototype to mass production, tailored to your exact needs |

| Quality Certifications | Ensuring industry standards and consistent product reliability |

| Fast Turnaround Time | Rapid development and delivery to keep your projects on schedule |

| Competitive Pricing | Optimized manufacturing lowers your costs without compromising quality |

We specialize in creating high-efficiency aluminum LED PCB boards and flexible 2835 LED strip PCBs that excel in heat dissipation and durability. Our dedicated team works closely with you to design custom LED circuit boards that improve longevity and performance.

Thanks to our proven track record and extensive portfolio, including detailed case studies and customer success stories, we provide solutions that meet diverse market demands.

For insight into our advanced PCB technologies, you can explore our work on round aluminum PCB LED designs and advanced LED assemblies like our LED quantum boards.

Partner with us for your 2835 LED light PCB board needs and experience superior product quality, reliability, and service.

Frequently Asked Questions about 2835 LED Light PCB Boards

How do I select the right color temperature for 2835 LEDs?

Choosing the right 2835 LED color temperature depends on where you plan to use the lighting. For cozy, warm environments like homes or hospitality, go for warm white (2700K–3000K). Offices and retail spaces often benefit from neutral white (4000K–4500K), while task lighting and commercial setups prefer cool white (5000K–6500K). If you need flexibility, consider tunable white or CCT-adjustable options.

Which PCB board offers better heat dissipation, aluminum or FR4?

Aluminum MCPCBs are superior for thermal management LED PCB solutions because they dissipate heat much more efficiently, extending LED lifespan and performance. FR4 rigid boards are more cost-effective for low- to mid-power applications but are not ideal for high-power 2835 LEDs. For in-depth insight on heat management, check out the advantages of aluminum LED PCBs.

What is the minimum order quantity for custom 2835 LED light PCB boards?

Minimum order quantities vary by manufacturer but typically start at a few hundred pieces. We specialize in custom LED circuit boards and can accommodate various order sizes, including prototypes and small batches for testing before scaling up production.

Are 2835 LED PCB boards compatible with dimmers and LED drivers?

Yes, most constant current LED PCB designs for 2835 LEDs are compatible with common dimmers and drivers. However, it’s important to select LED drivers and dimmers designed for the specific voltage and current requirements of your PCB setup. For more guidance on dimmer compatibility, our resources on PWM LED dimmer controllers can help you find the right match.

If you have any other questions about sourcing or customizing your 2835 LED light PCB boards, feel free to contact us directly!