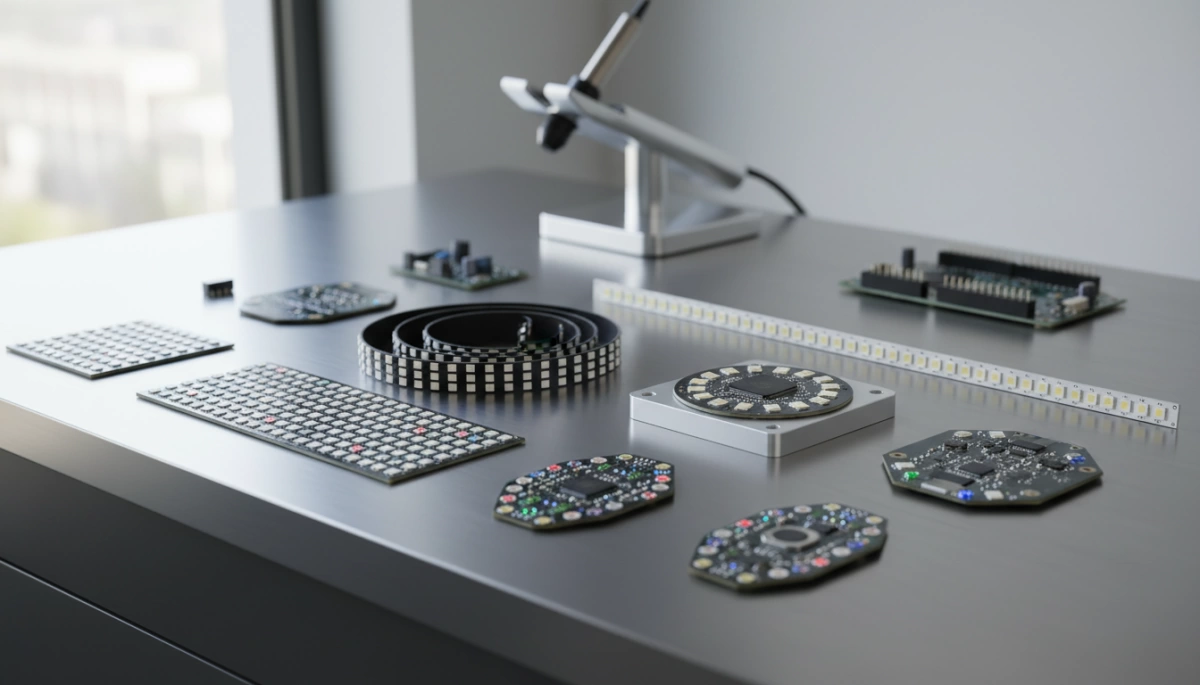

Common Shapes for LED Light PCBs

When choosing the shape of an LED light PCB, understanding common options helps match the design to the lighting purpose. Here’s a quick look at popular LED PCB shapes and where they shine:

| Shape Type | Typical Uses | Benefits |

|---|---|---|

| Rectangular & Linear | LED strips, edge-lit panels | Easy to scale, good for uniform lighting across surfaces |

| Circular & Round | Bulbs, downlights, spotlights | Provides even light spread, fits round fixtures naturally |

| Square | LED modules, arrays | Simplifies modular design, space-efficient layout |

| Flexible & Custom Contours | Curved installations, wearable LEDs | Adapts to shapes, allows for unique lighting forms |

Rectangular & Linear Shapes

Most commonly seen in LED strips and light panels, rectangular and linear PCBs allow efficient placement of LEDs in rows or grids, ideal for consistent and elongated light output.

Circular & Round Designs

These are chosen for bulbs and downlight fixtures, promoting even illumination. Round PCBs fit well inside cylindrical casings and round lighting housings without wasting space.

Square Configurations

Widely used in modular LED arrays or small light boards where the compact shape maximizes LED density and eases mounting or integration into larger systems.

Flexible & Irregular Shapes

Flexible LED PCBs enable lighting on curved surfaces or tight spaces. They are perfect for wearable LEDs, automotive accents, or architectural lighting where traditional rigid boards can’t fit.

Which Shape Works Best?

- Panels and strips: Rectangular or linear boards are the best choice for flat, broad areas.

- Bulbs and spotlights: Round PCBs provide smooth, balanced light distribution.

- Custom applications: Flexible or uniquely shaped boards solve tight or curved installation challenges effectively.

Selecting the right shape directly impacts how the LED light performs and fits into the final product, making it crucial to consider the overall design environment early on.

Typical Sizes and Dimensions of LED PCBs

LED PCB sizes vary widely depending on their intended use. For small-scale boards, compact modules around 20mm by 20mm are common. These fit well in portable devices or embedded lighting fixtures where space is tight but reliable illumination is still needed. Moving up, medium-sized boards typically include standard LED strips ranging from 8 to 15mm in width and square panels around 100mm by 100mm. These sizes suit indoor applications such as residential lighting or commercial displays, balancing flexibility and output.

For larger projects like industrial or street lighting, larger LED PCBs can reach up to 500mm by 500mm. These extended panels provide sufficient surface area to accommodate multiple LEDs, enabling higher light intensity and better heat management. The PCB size often depends on the LED package used — integrating popular SMD sizes like 2835 or 5050 chips influences overall dimensions and layout. For instance, the 2835 SMD LED footprint lends itself to high-density boards that maximize brightness in a compact area.

In practice, these varying sizes serve distinct applications: compact PCBs find their place in automotive interiors or wearable gadgets, medium panels light up retail environments, while large boards cater to outdoor or industrial setups. You can explore examples of different LED PCB boards incorporating these sizes in the 2835 LED light PCB board and LED strip PCB board categories, showcasing how dimensions align with performance needs.

Key Factors Influencing Shape and Size Selection

When deciding on the shape and size of an LED light PCB, several critical factors come into play to ensure the board performs well and fits the intended application.

Application and Mechanical Constraints

The PCB must fit perfectly within the light fixture’s enclosure. Space limitations and mounting demands often dictate whether a slim, elongated strip or a compact module works best. For example, automotive lights may require tight, irregular shapes, while street lighting typically allows larger, rectangular boards.

Thermal Management Needs

Heat dissipation is vital, especially for high-power LED modules. Larger surface areas or aluminum-based boards help manage thermal buildup, preventing premature LED failure. Choosing a size that balances compactness with enough area for efficient heat spread is key for durability and steady performance.

Electrical and Optical Considerations

The layout affects current flow and uniform light distribution. Proper spacing of LEDs—based on common SMD LED footprint sizes like 2835 or 5050—ensures even brightness without hotspots. Electrical pathways and connection points also influence the board’s shape to minimize power loss and maintain consistent output.

Material Choices: Rigid vs. Flexible

Rigid materials provide sturdy, dimensionally stable boards primarily for straight or square designs. Meanwhile, flexible LED strip PCBs allow for curved or unusual shapes, opening up new design possibilities for contour-fitting lighting installations. Your choice here directly impacts the final PCB shape and installation options.

Cost, Manufacturability, and Durability

Larger or unusually shaped boards can increase manufacturing complexity and cost. Plus, environmental factors like moisture or vibration resistance might demand specific materials or coatings, affecting size and shape decisions. Finding a balance between performance, price, and long-term reliability is essential.

By carefully assessing these aspects, we help tailor custom LED light PCB board designs that meet both technical specs and practical needs. For more on flexible PCB options, check out our insights on flexible LED strip PCBs.

Advantages of Custom LED Light PCB Boards

Custom LED light PCB boards bring clear benefits, especially when standard options just don’t cut it. One of the biggest advantages is the tailored fit for your unique project needs. Whether you need a specific shape, size, or mounting type, a custom design ensures the PCB matches perfectly with your product’s enclosure and mechanical constraints.

Another major plus is enhanced performance. Optimized layouts help improve electrical flow and heat dissipation, which boosts the overall reliability and lifespan of your LED modules. You can also integrate advanced features like special connectors, thermal pads, or flexible circuits that standard off-the-shelf boards often lack.

Flexibility is key when it comes to custom LED PCB designs. It allows manufacturers and designers to experiment with unconventional shapes or combine multiple LED types in one board. This adaptability is especially useful for intricate lighting installations, automotive parts, or decorative applications where off-the-shelf boards might limit your creativity.

Long-term reliability and energy efficiency also improve with custom LED light PCB boards. By addressing specific power and thermal requirements upfront, the board can handle higher loads without overheating or failure, saving costs on maintenance and replacements over time.

In short, a custom led light pcb board solves many limitations posed by generic units — from fitting irregular spaces to supporting specialized lighting functions. If your project demands precision and durability, going custom is a smart route. For more insight on tailored LED PCBs and their design benefits, check out our details on custom LED PCB shapes.

Design Considerations for Optimal Shape and Size

When planning the shape and size of an LED light PCB, striking the right balance between efficient heat dissipation and compact design is crucial. High-power LED modules generate significant heat, so providing enough surface area or using metal core PCB shapes can help manage thermal loads without making the board overly large.

Component placement plays a vital role in achieving uniform illumination. An even layout ensures consistent light output and reduces hotspots, which is especially important in square or rectangular LED PCB dimensions commonly used in lighting panels. Thoughtful spacing also supports reliable current distribution and prevents electrical issues.

Mounting and connectivity options should be integrated early in the design process. Including mounting holes, connectors, or flexible PCB sections allows the PCB to fit smoothly into its final housing or fixture, accommodating installation constraints while maintaining structural stability.

Meeting industry standards for safety, electromagnetic compatibility, and performance is non-negotiable. This compliance not only safeguards end-users but also improves long-term product reliability, particularly for commercial or automotive LED applications.

When working with manufacturers on prototypes, clear communication about your desired custom LED PCB shapes and size specifications is essential. Sharing detailed layouts, expected mechanical limits, and thermal requirements will streamline production and avoid costly revisions. Many specialists at reputable suppliers offer valuable insights during early-stage design discussions, helping optimize your LED PCB board for better performance and manufacturability.

For a deeper dive into the technical aspects of LED circuit board design, exploring expert resources like design considerations for LED circuit boards can provide further guidance tailored to your project’s requirements.